| Principle 7. | Businesses should support a precautionary approach to environmental issues. |

| Principle 8. | Businesses should undertake initiatives to increase environmental responsibility. |

| Principle 9. | Businesses should promote the development and diffusion of environmentally sound technologies. |

Our approach to management

We recognize the nature and scale of the impact of our activities and relate them to the importance of sustainable use of natural resources, protecting the health of our employees in all business areas and the communities in which we operate, and preserving a healthy environment.

The Company has made significant progress in making its operations more environmentally friendly. This is due to the implementation of effective internal standards, an environmental culture and continuous improvement of the management system. The Company has a “zero result” target aimed at avoiding negative environmental impacts.

Health, Safety and Environment (HSE) management objectives are directly linked to the KMG Group’s 2031 Development Strategy (hereinafter referred to as the Strategy). The Strategy includes strategic initiatives to increase environmental responsibility. Priority areas for KMG Group in terms of environmental protection include management of air emissions, reduction of flaring of crude gas, water management, production waste and land reclamation, and biodiversity conservation.

The management of KMG and its subsidiaries and affiliates follows the principle of zero tolerance for losses and damages related to environmental pollution. In accordance with the requirements of the new Environmental Code, the Company is guided by KMG’s Environmental Policy to ensure the collection, storage, analysis and dissemination of environmental information in its operations.

The Company has adopted an Emissions Management Policy consisting of eight key principles, six of which are directly related to climate change issues, aimed at completely eliminating regular gas flaring.

In an effort to minimize the regular flaring of crude gas, in 2015 the Company supported the World Bank’s “Zero Routine Flaring by 2030” initiative. One of our most important tasks in reducing atmospheric emissions is to increase the beneficial use and utilization of associated petroleum gas and to minimize gas flaring. Crude gas flaring volumes under this initiative are reported on an annual basis to the World Bank office in Kazakhstan.

In 2018, the Corporate Water Management Standard was adopted, which postulates KMG’s core principles in terms of water use – the 8 Water Principles – and systematizes the approach to water management. We adhere to strict principles in the use of water resources. We have now embarked on several large-scale projects to treat wastewater and saline water for production purposes in order to free up volumes of freshwater for the benefit of the population. The KMG Group’s Water Management Program is planned to be developed in 2023.

Health, Safety and Environment (HSE) Management System

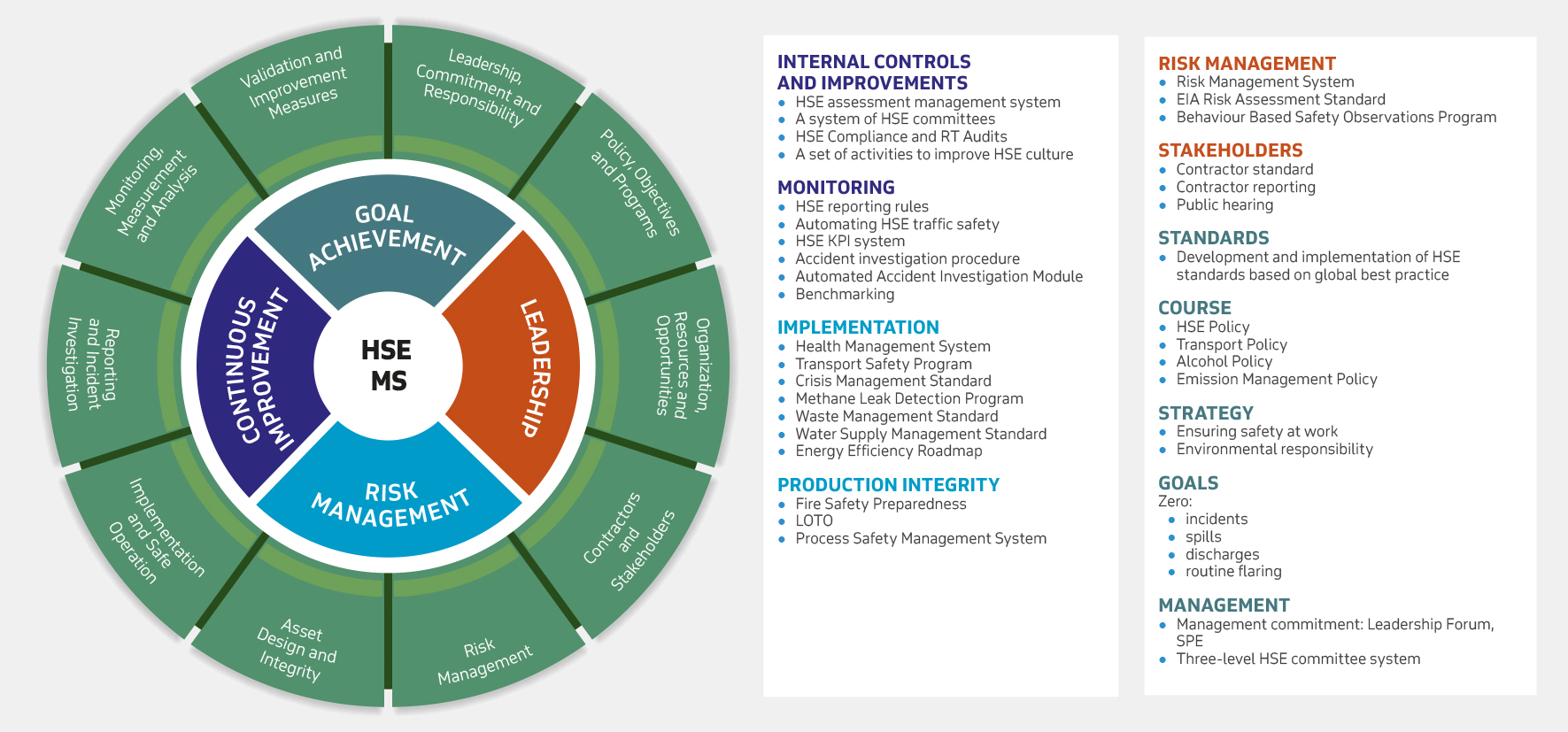

The Health, Safety and Environment Management System (MS) has been developed in accordance with the requirements of laws of the Republic of Kazakhstan, industry and international ISO standards, using global best practices and approaches, and the recommendations of the International Association of Oil and Gas Producers (IOGP), and includes 10 key elements that are based on such fundamental principles as leadership, goal achievement, risk management, and continuous improvement.

Since 2006, KMG has implemented an integrated quality, environment, health and safety management system (IMS) in accordance with ISO 9001, ISO 14001 and ISO 45001. Subsidiaries and Dependent Entities (SDEs) with significant energy consumption are certified to the ISO 50001 standard. The effectiveness of the IMS is regularly confirmed by independent auditors. To improve its management system, KMG is certified for Occupational Health and Safety Management System for compliance with the international standard ISO 45001.

Taking into account best and emerging practices in health, safety and environment (HSE) management, a three-level committee system has been introduced and implemented to increase the commitment and involvement of managers at all levels and employees in HSE management processes:

- First Level – the Health, Safety, Environment and Sustainability Committee of KMG’s Board of Directors (HSESC);

- Second Level – the HSE Committee at KMG level;

- Third Level – the HSE Committees of SDEs.

Since 2019, the Health, Safety and Environment Committee has been functioning at the level of Samruk-Kazyna JSC. In 2022, KMG took an active part in the work of this Committee and of the Committee’s Expert Group. As part of the work of the Committee and the Expert Group, Samruk-Kazyna JSC’s portfolio companies actively exchange experience, develop common approaches to HSE and participate in cross-audits of other portfolio companies. Many of KMG’s approaches and guidance documents on HSE have been adopted by other portfolio companies as best practices.

HSE reports are reviewed by the KMG Board of Directors on a monthly basis, with detailed informative reports reviewed by the HSESC. The following key topics were discussed in detail at the 2022 HSESC meetings:

- Crisis and Emergency Management in KMG Group;

- Waste Management, Status of Implementation of the Historic Waste Management Memorandum;

- Automation and Digitalization of HSE Projects;

- Measures to Improve Fire Safety in KMG Group;

- KMG’s Environmental Projects.

To meet the key objectives of KMG’s business continuity and environmental performance, the Committee was also briefed on the following HSE issues in 2022:

- Report on health, safety and environmental issues (at each Committee meeting);

- Approval of the Corporate Occupational Health and Safety Standard “Vital Regulations” for employees of KMG Group;

- Occupational health and safety management system;

- Management of KMG’s contractors;

- Report on COVID-19 situation in KMG (at each Committee meeting).

HSE risks, including environmental, climate change and water scarcity risks are monitored on a quarterly basis. KMG regularly analyses environmental performance and benchmarks against leading international oil and gas associations (IOGP, CDP). The Company pays particular attention to environmental aspects and environmental risk assessment.

KMG’s Health, Safety and Environment Department holds an annual Group Health, Safety and Environment (HSE) CEO Forum.

CASE STUDY

On 8 September 2022, the Seventh Annual Forum “Occupational Health and Safety Leadership. New Challenges and Approaches” was held. Members of the Board of Directors and management of Samruk-Kazyna and KMG, CEOs of more than 30 subsidiaries and dependent entities (SDEs), representatives of government authorities and a number of KMG’s foreign partners were invited to the forum.

Welcoming the forum participants, Mr. Magzum Mirzagaliyev, Chairman of KMG’s Management Board, stressed, “people are the company’s highest value and our main goal is to preserve the lives and health of all employees. For all KMG employees, strict adherence to the requirements of labour and production discipline and ensuring a culture of safe production must become the highest priority”.

Christopher John Walton, Chairman of KMG’s Board of Directors, also noted in his speech the crucial importance of personal example and the management’s attitude towards the goal of zero injuries and accidents at work.

The report by Kairat Saktaganov, Director of KMG’s HSE Department, summarized the year’s result, named the Group’s successful and underperforming companies, and showed KMG’s corporate HSE Performance Wheel model, which compactly and visually presented 12 areas that SDEs should work on systematically to achieve zero incidents.

The forum also included a discussion session, where CEOs of a number of companies shared their experiences and cases of occupational safety culture and talked about various HSE projects.

At the HSE awards ceremony, it was stated that all forum participants were united by the common goal of creating a systematic corporate safety culture. Awardees: Atyrau Refinery LLP (for effective implementation of corporate safety and health initiatives), Embamunaigas JSC (for successful implementation of the road safety project), Karazhanbasmunai JSC (for contribution to environmental protection), KazTransOil JSC (for effective implementation of best practices in emergency and crisis management), JV CASPI BITUM LLP (for HSE leadership and commitment) and Mangistauenergomunai LLP (for effective implementation of industrial safety tools).