KMG Group is focused on reducing the impact on the environment and preserving biodiversity, as well as on the sustainable use of natural resources.

We understand the degree of responsibility to society for correct use of natural resources and for maintaining a favourable environmental situation in the regions where we are present. We are committed to using natural resources sustainably, reducing our impact on the environment and introducing technologies, equipment and materials that promote energy and resource conservation, create minimal waste and do not harm the environment. We are taking measures to adapt to climate change and to compensate for possible environmental damage.

To this end, a number of activities aimed at ensuring environmental safety have been implemented, such as work on disposal of historical oil waste and treatment of oil-contaminated land, strengthening environmental awareness among employees, participation in tree planting campaigns, development of action plans to reduce atmospheric emissions, implementation of environmental protection programs and other activities.

A number of the Company’s subsidiaries and affiliates have implemented the automated air quality monitoring systems at the sanitary protection zone, as well as directly at emission sources, which display information on the state of the environment.

Automated Environmental Monitoring Information System Project

The aim of the project is: to create a unified environmental information space; to increase transparency, efficiency and minimize human error in order to avoid potential environmental fines.

The main objectives of the AEMIS are:

- Automation of processes of environmental reporting to public authorities;

- Maintenance of a database of regulatory permits and calculation of payments for environmental emissions;

- Prompt response to potential excess emissions by promptly correcting faults in the process by the production units;

- Operational environmental monitoring based on the results of industrial environmental control;

- Generation of corporate reports via synchronization with HSE system of KMG.

Key performance indicators for 2022

- SOx emission rate – SOx – 0.21 (IOGP – 0.20)

- NOx emission rate – 0.31 (IOGP – 0.33)

- Associated petroleum gas (APG) combustion rate – 1.5 (IOGP – 9.4)

- APG utilization rate – 98.8 %

- Rehabilitation of historical waste and oil-contaminated land: 693.7 thousand tons (2021: 540.5 thousand tons)

- CDP climate rating: C

- CDP water safety rating: C

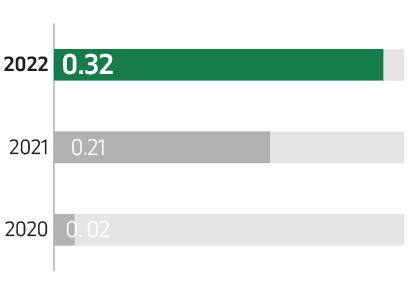

Environmental performance, t/1,000 toe of HC production

|

Year |

SOx emission rate |

NOx emission rate |

APG combustion rate |

Crude gas utilisation rate, % |

|

2020 |

0,23 |

0,22 |

2,20 |

98 |

|

2021 |

0,22 |

0,24 |

2,09 |

98 |

|

2022 |

0,21 |

0,31 |

1,5 |

98,8 |

Air Protection

KMG pays special attention to environmental issues, as they are directly linked to the health and well-being of the population. One of KMG Group’s environmental policy objectives is to continuously improve its environmental processes through digitalization.

KMG’s priority areas in terms of environmental protection include management of air emissions, reduction of crude gas flaring, management of water resources, production waste and land reclamation, and biodiversity conservation.

By reducing gas flaring, we have also managed to reduce air pollutant emissions at all of the KMG Group’s facilities.

One of the key areas for minimizing the environmental impact is the reduction of air pollutant emissions from the Company’s production activities. The following works are being carried out as part of the activities to reduce air pollutant emissions:

- Technically obsolete burners on oil heating furnaces are being replaced in stages.

- Integrated gas treatment and processing facilities are under construction.

- Work is underway to install pontoons for vertical oil tanks to prevent evaporation of hydrocarbons.

- Catalytic converters for pollutant emissions are being installed on oil heating furnaces, etc.

- The condition of the furnace burners is being monitored systematically, according to the schedule of maintenance and adjustment work.

- The water injection system is being expanded by transferring wells from production to injection.

- The wellhead equipment of production oil wells has been updated.

- New steam generation and well sites have been commissioned.

- A medium-pressure inter-flare injection burner has been installed, designed to burn oil and associated gases in the furnaces of boilers and oil and water reheating furnaces.

KMG Group pays special attention to monitoring environmental and natural resource emissions from its production facilities, primarily those located near or within the boundaries of populated areas. KMG works continuously to monitor environmental components (air, water resources, soil cover, etc.) and to effectively reduce the adverse environmental impact of its operations.

Environmental monitoring is an integrated system of observations, measurements, collection, accumulation, storage, recording, systematization, compilation, processing and analysis of data obtained on environmental quality, as well as generation of environmental information on the basis thereof, provided by the state.

To ensure air quality in populated areas, KMG Group is implementing projects to reduce the level of air pollutants, and is also taking measures to organize air quality control systems and install stationary air quality observation posts at the boundaries of sanitary protection zones.

In accordance with Article 418 (16) of the Environmental Code of the Republic of Kazakhstan, from 1 January 2023, the requirement for a mandatory automated emission monitoring system (hereinafter referred to as AMS) applies. “The real-time AMS monitors nitrogen oxide, nitrogen dioxide, carbon monoxide in waste gases and measures flow rate, temperature, pressure and relative humidity.”

Two oil and gas SDEs were the first among the Group’s companies to launch AMS. For example, the integrated AMS equipment was installed at the gas turbine power plant (GTPP) of the Kalamkasmunaigas Production Department and was successfully tested. Commissioning of such unique systems is not only an important step in the modernization of plants, but also increases environmental efficiency and transparency.

KMG Group Operators are responsible under the new Environmental Code for emissions from contractors which are technologically directly related to the operations of the facility Operator and which work on their premises. Emission data from contractors has been accounted for in the unified environmental permit and included in the Operators’ reporting, therefore there is an 8.6 % increase in air pollutant emissions compared to 2021.

As a result of the refinery modernization projects, the environmental performance of the refineries has been improved by producing oil products of European quality standards corresponding to classes K4-K5, in accordance with the requirements of the Technical Regulations of the Customs Union.

Gross air pollutant emissions in KMG Group, thousand tons

|

|

2020 |

202114 |

2022 |

|

Air pollutant emissions, total, including: |

247.2 |

110.2 |

120.6 |

|

NOx emissions |

17.6 |

12.7 |

16.0 |

|

SOx emissions |

12.7 |

12.2 |

10.5 |

|

other pollutant emissions |

216.9 |

85.3 |

94.1 |

14 Note: From 2021 onwards, data exclude KTG.

Specific pollutant emissions in KMG Group

|

|

2020 |

2021 |

2022 |

|

HC production, t/1,000 toe of HCs produced |

1.9 |

1.9 |

2.1 |

|

Oil refining, t/1,000 t of oil refined |

2.9 |

2.8 |

3.1 |

|

Oil transportation, t/1,000 t of oil transported |

0.5 |

0.5 |

0.5 |

n 2022, the average rate of NOx emissions to total hydrocarbon production in oil equivalent in KMG Group was 0.31 tons per thousand tons of hydrocarbon production and the average IOGP was 0.33. Compared to 2021, specific NOx emissions have increased by 29 % due, as noted earlier, to the addition of new sources from contractors. The average rate of SOx emissions to total hydrocarbon production in oil equivalent in KMG Group was 0.21 tons per thousand tons of hydrocarbon production and the average IOGP was 0.20. Compared to 2021, there is a 4.5 % decrease in specific SOx emissions.

The Company does not emit any persistent organic pollutants in its operations.

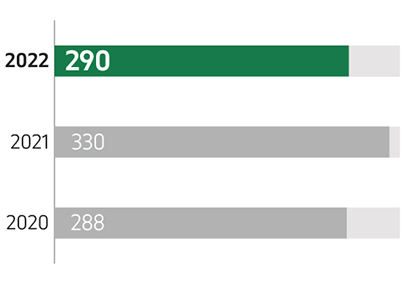

Rational use of crude gas

One of the priority objectives for KMG and its subsidiaries is to manage emissions of harmful substances and greenhouse gases into the atmosphere and to reduce gas flaring. According to the Environmental Policy, our Company aims to achieve zero flaring and reduced emissions from flares. We aim to increase the use and utilization of crude gas and minimize flaring. Through our crude gas development and processing programs, we have increased the use of gas for heat and power generation, resulting in lower emissions of harmful substances and greenhouse gases from the combustion and emission of crude gas.

In 2022, crude gas utilization was 98.8 %. Flaring of raw gas decreased by 89 % compared to 2017 (2017 volume: 315.8 million m3). The gas flaring rate is 1.5 tons per thousand tons of hydrocarbon production (2021: 2.1, 2020: 2.2), which is 29 % below the 2021 figure and 84 % below the IOGP industry average.

In 2015, KMG supported the World Bank’s “Zero Routine Flaring by 2030” initiative. The Company aims to minimize the crude gas flaring. Crude gas flaring volumes under this initiative are reported on an annual basis to the World Bank office in Kazakhstan.

Crude gas flaring volume

|

KPI |

2020 |

2021 |

2022 |

|

Total crude gas flaring volume, million m3 |

57.6 |

52.5 |

35.7 |

|

Crude gas utilization rate, % |

98 |

98 |

98.8 |

|

Crude gas flaring rate, t/1,000 t of hydrocarbon production |

2.2 |

2.1 |

1,.5 |

This Section reflects information on KMG companies in the upstream sector in which processes related to the production and beneficial use of crude gas take place.

Water management

The responsible use of water is an integral part of the Company’s values. The Company explores and produces hydrocarbons in regions with high water scarcity and is committed to the sustainable use of water resources. KMG also uses alternatives to fresh water in its operations: reused and recycled water, treated wastewater and desalinated water. In regions with high water scarcity, KMG is developing water management measures to use less fresh water, increase recycled water and closely monitor water use.

KMG’s main water use principles are the “Eight Water Principles”, which systematize the approach to water management in KMG SDEs. These principles are described in the Corporate Water Resources Management Standard: https://www.kmg.kz/en/sustainable-development/corporate-governance/corporate-documents/.

The Company is implementing projects aimed at reducing discharges and water withdrawals from natural sources. To improve the efficiency of water resources conservation and management and to identify measures and targets to reduce water withdrawal, increase recycling of water supply, a long-term Water Resources Management Program is planned to be developed in 2023 in KMG Group.

The Company operates in full compliance with international requirements and environmental and water legislation. The Company develops draft standards for pollutant discharges, conducts calculations in accordance with methodologies approved by the authorized body, obtains environmental permits and special water use permits.

Since 2020, the Company has been calculating its water footprint and posting water management information on the Carbon Disclosure Project site as part of the Water Security Questionnaire.

More detailed information can be found in the published KMG reports, which are publicly available at: CDP Water Security Questionnaire. https://www.cdp.net/en/responses?utf8=%E2 %9C%93&queries%5Bname%5D=Kazmunaygas

Information on Water Supply Projects can be found in the Section ‘Implementation of Investment Projects’.

Water footprint

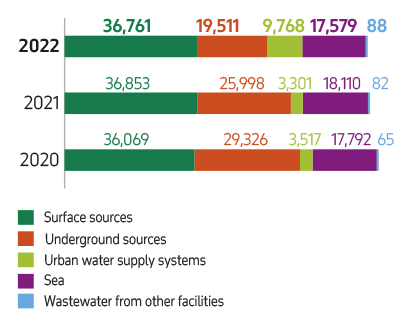

Water withdrawal by KMG Group by source, 83,707 thousand m3

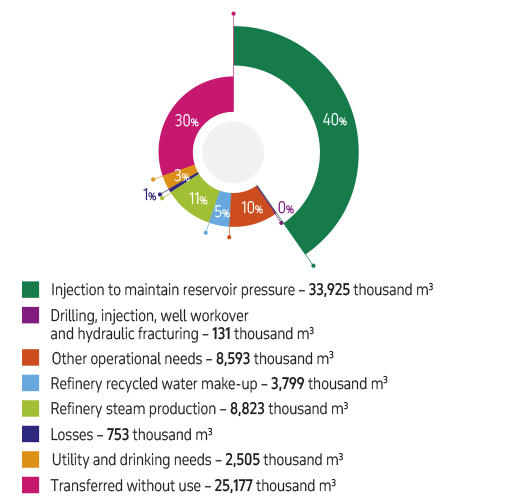

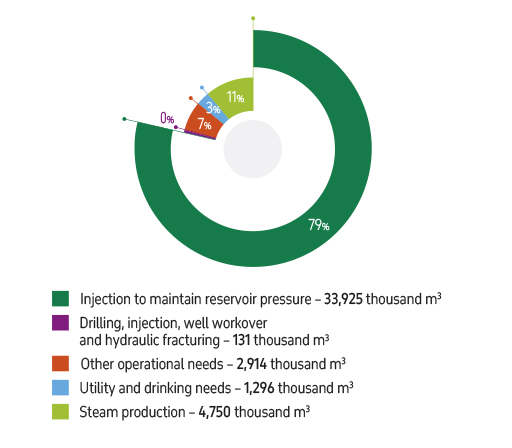

Water use by type of operation in KMG Group in 2022, %17

Water withdrawal by KMG Group in 2022 was 83.71 million m3, including: surface sources – 36.76 million m3, underground sources – 19.51 million m3, urban water supply systems – 9.7715 million m3, sea – 17.58 million m3, wastewater from other facilities – 0.09 million m3. Production water consumption by category with salinity up to 1,000 mg/l was 38.02 million m3 and by category with salinity of 1,000 mg/l or more was 45.69 million m3.

The Company also analyses and records the facilities of KMG SDEs located in regions with increased water scarcity according to the WRI Aqueduct16, relating to the basins of the Caspian Sea, the Syrdarya and the Ural Rivers. The total water withdrawal of these facilities was 29.81 million m3 (36 % of KMG Group’s water withdrawal).

In 2022, 10.69 million m3 of wastewater was diverted by KMG Group. Wastewater treatment plants treat the following high-priority pollutants: suspended solids, COD, BOD, petroleum products, chlorides, sulphates, iron, nitrites, nitrates, ammonia nitrogen, synthetic surfactants, etc. Pollutant discharge standards are calculated according to the Methodology for Determining Environmental Emission Standards approved by Order No. 63 of the Minister of Ecology, Geology and Natural Resources of the Republic of Kazakhstan dated 10 March 2021. After wastewater treatment in wastewater treatment plants, the effluent treated to standard quality is discharged to specialized receivers: storage ponds, evaporation fields and filtration fields. There is no discharge to surface water bodies or terrain. Facilities that do not have their own storage ponds transfer wastewater to specialized companies for treatment and discharge, according to the contracts signed. The total volume of wastewater transferred was 0.38 million m3 (with salinity above 1,000 mg/l). There is no discharge of wastewater with salinity up to 1,000 mg/l.

At the same time, the discharge of wastewater from facilities in regions with water scarcity was 2.65 million m3, of which 2.54 million m3 were discharged to their own receivers and 0.11 million m3 were transferred to specialized companies (receiving facilities).

Our wastewater treatment plants are designed to treat wastewater contaminated with petroleum products and suspended solids. At refineries, for example, wastewater is treated separately in parallel mechanically and physicochemically in sand traps, oil traps, radial sedimentation tanks and flotators. The treated industrial effluents after the flotators are fed to biological treatment.

15 The increase of water withdrawals from urban water supply systems and the corresponding decrease of water withdrawals from underground sources are related to the reclassification between water withdrawal sources: thus, in 2022, water from underground sources withdrawn by urban water supply systems was classified as water withdrawal from urban water supply systems, as opposed to 2021, where it was classified as water withdrawal from underground sources.

16 According to WRI Aqueduct: high category – total water load 40-80 %, extremely high category – > 80 %.

17 The direct method was used to collect data on water consumption for KMG Group.

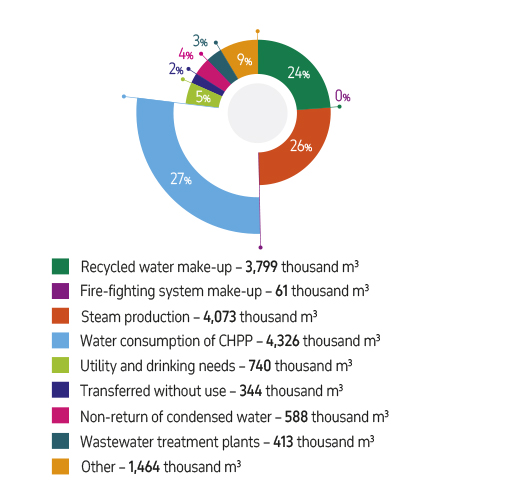

Water use by type of operation in the Downstream SECTOR in 2022, 15.81 million m3, %

WATER USE BY TYPE OF OPERATION IN THE UPSTREAM SECTOR IN 2022, 43.02 MILLION M3, %

Part of the wastewater after treatment is reused for vehicle washing, dust suppression and fire-fighting systems. However, a significant volume of treated wastewater is only reused at refineries, where 4.33 million m3 of treated wastewater was reused in 2022, mainly to feed water recycling units. The percentage of water reuse at KMG’s refineries was 27 % (of the volume of water withdrawal in the Downstream segment).

In 2022, a total of 451.27 million m3 was used (circulated) in the KMG refineries’ water recycling systems.

KMG refineries’ water recycling systems circulated

|

|

2020 |

2021 |

2022 |

|

Recycled water volume, million m3 |

430.62 |

389.99 |

451.27 |

The oil production process generates large volumes of so-called associated reservoir water – an oil-water emulsion is brought to the surface, which is subsequently separated into water and oil by gravity. Water settled in this way is fed for reinjection into the reservoir.

In total, of 136.52 million m3 of associated reservoir water produced in 2022, 99 % was re-injected to maintain reservoir pressure.

REINJECTED TO MAINTAIN RESERVOIR PRESSURE

|

|

2020 |

2021 |

2022 |

|

Associated reservoir water produced, million m3 |

125.37 |

13.,05 |

136.52 |

The Company’s activities have the most significant impact on water bodies in the western region of Kazakhstan (the Ural and the Kigach rivers, and Kokzhide sands), which are of special environmental, economic, historical, cultural and recreational value. To prevent negative impacts on sensitive ecosystems, regular environmental monitoring is carried out by the regulatory authorities.

Waste Management and Land Reclamation

KMG’s production activities generate production and consumption waste: drilling waste (drilling mud and sludge), oily waste (bottom sediments, oil-contaminated soil, oil sludge, well backwash waste), waste catalysts and chemicals.

All facilities also generate waste from ancillary activities such as construction waste, oily rags, waste lubricating oil, etc.

KMG strives to strictly comply with the principles of the state environmental policy in the field of waste management, as well as the implementation and enforcement of the principles of KMG’s Environmental Policy in relation to waste management:

- Ensure that waste generation is reduced and handled safely.

- Apply a set of waste recovery technologies that prevent secondary contamination of soil, air or water resources.

- Introduce resource-efficient, low-waste, environmentally friendly technologies.

Waste generated at the facilities is collected separately at the initial stage of generation, generated waste is weighed on weighing equipment, for liquid waste the volume of waste is measured in standardized or graduated containers.

All KMG facilities maintain records of waste by type, quantity and properties, develop hazardous waste data sheets, and maintain records of production and consumption waste in an appropriate waste log as waste is generated and transferred for recovery or removal. Responsible persons for waste management have been appointed at all production facilities.

The results of waste recording are submitted to the authorized environmental authority in the form of the following documents: industrial environmental control reports (quarterly), waste inventory reports (annually), register of emissions and transfer of pollutants (annually), and to KMG via the KMG HSE information system.

From the moment waste is generated, KMG SDEs accumulate waste, bury it or transfer it for recovery and/or disposal by their own efforts or by engaging specialized waste recovery or removal companies in accordance with the approved Waste Management Program.

KMG SDEs apply the following hierarchy of waste management measures in descending order of preference for environmental protection and sustainable development of the Republic of Kazakhstan:

- prevention of waste generation;

- waste recovery (recycling or disposal);

- waste removal.

Specialized companies involved in waste recovery or removal must have all the necessary permits:

- License for the treatment, neutralization, recycling and/or disposal of relevant hazardous waste.

- Notification of the commencement of collection, sorting and (or) transportation of waste, recovery and (or) disposal of relevant non-hazardous waste.

- Environmental permit.

To reduce the impact of waste during transportation, KMG SDEs have established requirements for specialized companies to minimize the movement of waste or its recovery within KMG SDEs.

Engaged specialized companies carry out waste recovery operations at KMG SDEs using methods stipulated by their environmental permits; it is important to note that when selecting waste recovery methods at KMG SDEs, priority is given to modern waste recovery technologies, including those without secondary contamination of the environment.

Work on the recovery of newly generated and previously accumulated waste by specialized companies is controlled by KMG SDEs for compliance with the technical specifications of the contract signed and the design solutions for waste recovery and removal, including visits to waste recovery facilities, if necessary control laboratory analyses of the recovered waste are carried out.

In 2022, KMG spent KZT 14.37 billion on recovery of generated and accumulated waste.

Work also continues on the disposal of historical oil waste and the clean-up of oil-contaminated land at MMG, OMG and KBM facilities under the Memorandum of Cooperation between the Ministry of Ecology, Geology and Natural Resources of Kazakhstan and KMG dated 6 August 2019.

OMG sludge storage pit before and after cleaning

As part of the implementation of the Memorandum, inventories of MMG, OMG and KBM contract areas have been made since September 2019 to identify waste characteristics, oil product content of the waste and volumes of waste.

On the basis of the inventories made, relevant oil-contaminated land reclamation projects have been developed and agreed upon with the state authorities, safe and efficient oil-contaminated waste disposal technologies have been selected and recommended within the projects, oil waste disposal facilities have been built, and relevant permits and licenses have been obtained.

CASE STUDY

Embamunaigas JSC has an ATR-300 tyre recycling facility that can recycle used tyres from trucks and cars, as well as some types of tyres from special machines. The output is three types of rubber crumb fraction. The facility is a process line with a series of units, passing through which the raw material takes on the form of a finished product.

The process is zero-waste:

- when recycling tyres, the output of the end product is 60 % crumb rubber;

- 30 % of metal waste from cord and bead ring are subsequently used in the manufacture of reinforced concrete products;

- 10 % textile cord waste is used as insulation material.

Oil waste disposal facility built on MMG’s site

In addition, although EMG and KBM are not included in the extent of obligations under the Memorandum, there is also work to remediate historical contamination, these companies have completed work in 2022 to clean up historical oil contaminated land within the contract areas.

In 2022, 693.7 thousand tons of historical waste were disposed of at the facilities of KMG SDEs and the places of their disposal were reclaimed.

Waste transferred for recovery and removal (tons)

|

|

On SDEs’ site |

On Contractor’s site |

Total |

|

Hazardous waste |

|

|

|

|

Waste recovery (recycling/disposal) |

727,469 |

362,315 |

1,089,784 |

|

including drilling waste (drilling mud and sludge) |

-- |

220,380 |

220,380 |

|

Waste removal (burial/placement) |

7,615 |

-- |

7,615 |

|

including drilling waste (drilling mud and sludge) |

-- |

-- |

-- |

|

Non-hazardous waste |

|

|

|

|

Waste recovery (recycling/disposal) |

1,604 |

17,899 |

19,503 |

|

Waste removal (burial/placement) |

1,015 |

14,430 |

15,445 |

|

Total |

1,132,347 |

||

Waste composition (tons)

|

|

Waste generated |

Waste sent for recovery |

Waste sent for removal |

|

Hazardous waste |

382,37718 |

1,089,78419 |

7,615 |

|

including drilling waste (drilling mud and sludge) |

222,191 |

220,380 |

-- |

|

Non-hazardous waste |

37,170 |

19,503 |

15,445 |

|

Total waste |

419,547 |

1,109,287 |

23,060 |

In 2022, the total area of disturbed land reclamation was 109 hectares.

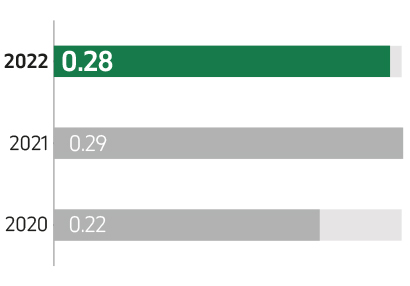

Ratio of recycled waste to accumulated and newly generated waste, t/t

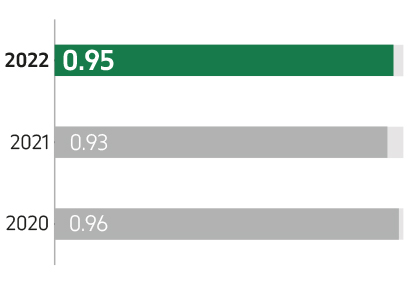

Ratio of recycled waste to newly generated waste, t/t

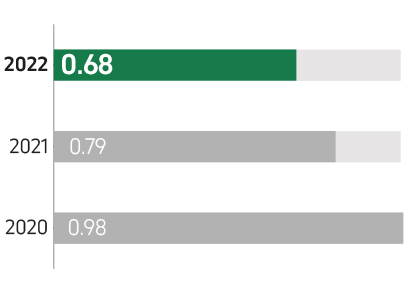

Ratio of contaminated land area at the end of the year to the beginning of the year, ha/ha

Ratio of reclaimed land area to contaminated land area during the year, ha/ha

18 The amount of generated waste is presented taking into account the waste generation volume by contractors performing the works in KMG Subsidiaries and Dependent Entities territory.

19 Taking into account the volume of historical waste disposal, as well as the volume carried over from the previous year.

Abandonment and reclamation of work sites

Under the terms of specific contracts, in accordance with applicable law and regulatory acts, KMG is under legal obligation for decommissioning and disposal of main assets and land reclamation in each of the fields. In particular, KMG obligations include the gradual abandonment of all unproductive wells and actions for the termination of operations, such as the dismantling of pipelines, buildings and reclamation of the contract area, as well as decommissioning and obligations for environmental pollution in the production site.

The Company calculates obligations for disposal of assets separately for each contract. As of December 31, 2022, the inventory value of the Group reserve upon liabilities for the removal of oil and gas assets amounted to 88,163 million tenge. The processes of reclamation and abandonment the contract areas are regulated by the Code of the Republic of Kazakhstan dated December 27, 2017 No. 125-VI ZRK ‘On Subsoil and Subsoil Use’.

According to the Code of the Republic of Kazakhstan ‘On Subsoil and Subsoil Use’:

- The remediation of the consequences of subsoil use shall be performed in accordance with the project of remediation of the consequences of subsoil use approved by the subsoil user and received positive conclusion of examinations provided for by this Code and other laws of the Republic of Kazakhstan.

- The conservation of the subsoil area shall be performed in accordance with the project of the conservation of the subsoil area approved by the subsoil user and received positive conclusion of examinations provided for by this Code and other laws of the Republic of Kazakhstan.

- Production facilities shall be liquidated or closed in accordance with the project of liquidation or conservation of production facilities approved by the subsoil user and received positive conclusion of examinations provided for by this Code and other laws of the Republic of Kazakhstan, with the exception of certain categories of wells provided for in the rules for conservation and liquidation when hydrocarbons prospecting and production, approved by the authorized body in the field of hydrocarbons, which liquidation or conservation shall be subject to the liquidation and conservation plan.

The requirements for the works on the liquidation of wells are established in the rules for conservation and liquidation when hydrocarbons prospecting and production and uranium mining, approved by Order from the Minister of Energy of the Republic of Kazakhstan dated May 22, 2018 No. 200. It is registered with the Ministry of Justice of the Republic of Kazakhstan on June 19, 2018 No. (Chapter 4. Liquidation of oil, gas and injection wells of different purpose when hydrocarbons prospecting and production).

Oil trunk lines

In accordance with the Law of the Republic of Kazakhstan ‘On trunk pipeline’, with effect from July 4, 2012, KazTransOil JSC (hereinafter referred to as KTO) is lawfully bound to decommission the trunk pipeline when completion of operation and carry out subsequent measures to remediate the environment, including land reclamation. The liability reserve for pipelines decommissioning and land reclamation is estimated based on the cost of dismantling and reclamation work calculated by the Group. As of December 31 2022, the book value of the Group liability reserve for pipelines decommissioning and reclamation of Group lands amounted to 40.6 million tenge (as of December 31, 2021: 34.5 million tenge).

CASE STUDY

In 2022, preparatory works were carried out jointly with LUKOIL PJSC and the exploration well drilling in Zhenis site began in December. The Zhenis Block is located in the Kazakhstani Sector of the Caspian Sea at a depth of 75-100 m. The distance from the block to the port of Aktau is 180 km, the license area is 6,848 sq. km. In accordance with the signed contract, the drilling of one exploration well and conducting 3D seismic surveying are the main minimum obligations. The operator of this project is Zhenis Operating Joint Venture in which each company owns 50 %.

The projects in the Caspian Sea is an important step in expanding the resource base in the region which has a strategic importance for the Company and where it has accumulated considerable expertise. In 2023 it is planned to complete the drilling of an exploration well in the Zhenis site, carry out preparatory works for drilling at the Abai site, and conduct seismic exploration at the Al-Farabi site.

Offshore well management

In the Kazakhstani Sector of the Caspian Sea, KMG, together with strategic partners, are conducting the geological exploration works at Zhenis, Abai, Al-Farabi and other subsoil use sites. In accordance with Contracts for subsoil use and Joint venture agreements, geological exploration works on offshore projects are carried out by specially established joint ventures with international partners (Eni, LOKOIL, etc.). With this, management decisions on the processes of offshore drilling wells at sea and marine seismic works in joint ventures are made by KMG and Partners within the framework of Operations Committees and their subcommittees (financial, technical, HSE, procurement) in full accordance with international standards and the RoK legislation requirements. All responsibilities related to the management of offshore wells are set out in the Regulations on the Operations Committee and in the Joint venture agreements.

Oil spill prevention and response

The Caspian Sea is an unique natural object, which fragile ecosystem is particularly sensitive to oil pollution due to its confinement. We impose high requirements on environmental security when offshore oil operations: prior to the start of any type of work, we conduct baseline environmental studies in contract territories and assess our potential social and environmental impact, as well as we monitor the impact, emissions and emergency situations: during and after operations.

Before starting offshore drilling operations, we ensure permanent readiness for the elimination of all possible emergency oil spills. Upon completion of works, we conduct continuous environmental monitoring of the abandoned wells. Monitoring of abandoned wells in the contract territories includes monitoring of: atmospheric air quality, pollution of seawater and bottom sediments, the state of biodiversity, as well as laboratory-and-analytical activities, photo and video recording of the abandoned wells heads.

During offshore operations, we unfailingly follow next principles:

- Strict adherence to design decisions

- ‘Zero liquid discharges’ principle: all waste and wastewater are removed to the shore

- Provision of all floating crafts with fish protection devices and the absence of bilge waters

- Prohibition on carrying out production operations during the spawning period: from April 1 to July 15

- Prohibition of fishing from production vessels

- Prohibition on well testing and flaring of hydrocarbons at night

- Compliance with a special mode of use.

Volume of oil spill (tons)

The main cause of oil spills in the Company is ruptures of field oil pipelines under the influence of corrosion processes. Spills occur due to a collector rupture and a rupture due to wear of the steel part of the pipeline, followed by a spill.

The companies are carrying out operational activities on area cleanup from the oil contaminated ground with the transportation of water-oil to drainage tanks for further transfer to third-party organizations for treatment. Perennial grasses that correspond to the species composition in the process of biological reclamation have been planted.

With this, all cases in onshore facilities were recorded during the hydrocarbon production. There are no oil spills in offshore.

The Company carries on with work to reduce the number of failures and ruptures of field oil pipelines by timely and high-quality implementation of actions on diagnostics, reconstruction, replacement, inhibition and cleaning of pipelines aimed at improving their integrity and reliability.

In close cooperation with law-enforcement agencies, KazTransOil JSC reversed the situation with criminal illegal tie-ins into the Company pipelines. Over the past 3 years, the facts of tapping into trunk pipelines have been reduced to zero marker (in 2019, were identified 2 tie-ins, the damage amounted to 6.4 million tenge; in 2020 and 2021 2022 no facts of criminal tie-ins were recorded).

These indicators have been achieved largely due in no small part to the implementation of the following activities:

- strengthening the control over the monitoring of the work of mobile groups using GPS-systems and the timely implementation of detours and inspections of oil pipelines by mobile teams;

- protection of oil pipelines through the Optosense monitoring system.

Permanent readiness to oil spill response operations (OSR) is an absolute priority for us.

INITIATIVE TO PROMOTE THE VOLUNTEER MOVEMENT IN oil spill response operations

The KMG Group of Companies continues to pay attention to volunteering when OSR. The company KMG Systems&Service LLP implements the ‘Program for the volunteering development when OSR in Atyrau and Mangystau regions’ (hereinafter referred to as the Program), within which KMGSS LLP in 2022 conducted 4 trainings on the measures on mitigation of potential emergency oil spills for the volunteer movement ‘With the care of the Caspian’ on the Offshore Support Base (OSB) in Bautino village of Mangystau region. 67 volunteers and 4 employees of the Emergency Situations Department of Mangystau region were trained. A workshop was also held for post-secondary students in Atyrau.

The training included the core theory and practice of remediation activities of environmental pollution by oil. In particular, volunteers learn how to use special equipment to eliminate spills, and specifically, they participate in the deployment of booms – special bars to absorb oil spills. The main goal of the project is to transfer knowledge and train volunteers in the OSR basics and wildlife rescue.

Conservation of biodiversity and support of specially protected natural areas

Protected nature areas in the regions of our presence and affected species of flora and fauna

The Northern Caspian Sea is the most productive part of the Caspian Sea. The biological resources of this part of the sea are very large. The main fishing grounds of the ichthyofauna are 25 species, of which the most valuable are sturgeons, which make up in the basin more than 70-80 % of their world resources.

The water area of the eastern part of the Northern Caspian Sea with the deltas of the Volga (within the RoK) and Ural rivers is included in the state conservation area in the northern part of the Caspian Sea. The wetlands of the northern part of the Caspian Sea, and especially deltas of the Volga, Ural and Emba rivers, as well as the adjacent coast and the water area of the sea itself are the most important farmland on the Eurasian continent, which provide support for millions of waterfowl and semiaquatic birds during nesting, molting, seasonal migrations and overwintering. The Siberian-Black Sea-Mediterranean Flyway, one of the largest in Eurasia, lies through the Northern Caspian Sea.

According to baseline studies, more than 70 bird species migrate through open areas of the North-eastern Caspian Sea, 20-60 km away from the shore (5 of them are rare species listed in the Red Book of Kazakhstan). In the littoral zones, the little heron, the spoonbill, pelicans, the whooper swan, the Ferruginous Duck and the great black-headed gull nest. The purple gallinule, white-tailed eagle and osprey are also observed on the fly.

5 species from the RoK Red Book nest in terrestrial cenoses. The steppe eagle is the most numerous. What’s about the rare birds, it is possible to meet the avocet, oystercatchers, little heron.

The only large marine mammal (order pinnipeds) inhabiting the Caspian Sea is the Caspian seal (Phoca caspica). It is an endemic mammal species. Seals are prevalent throughout the Caspian Sea, but their number in the Northern part varies with the season. The pattern of the seasonal distribution of animals in the sea area is determined by three main phases of the annual cycle: reproduction, molting and fattening period. Breeding grounds are located in the North Caspian Sea, which freezes in winter. Seals spend the fattening period from April to September mainly in the Middle and Southern Caspian Sea. In summer, a small number of animals (about 30,000 specimens) inhabit the Northern Caspian Sea, the major stratum is located in the deeper and colder waters of the Southern Caspian. In late autumn, they migrate to the area of the Northern Shallow Water, where the water begins to freeze. Most of the stratum gathers in the Northern Caspian Sea in October-November.

Such an important territory for the conservation of the biodiversity of Kazakhstan and the entire Eurasian continent needs ongoing monitoring and timely implementation of conservation measures. From the beginning of its activity in the Northern Caspian Sea, KMG has been paying attention to the issues of nature protection in this region.

Isatai site is located in the northern part of the Caspian Sea, 45 km north of the coast of Bozashi peninsula, in Mangystau region.

Dead Kultuk (Ustyurt) is the inhabitation of the most specific representative of the Caspian Sea – flamingos, formerly prevaling in the northeast and still using this part of the sea, molting and non-breeding locally occurring birds in the area of Komsomolets Bay and Dead Kultuk and Kaidak sors. Flamingo (Phoenicopterus roseus) are a locally nestling decreasing specie. It is the only representative of the genus in the fauna of Kazakhstan. The main breeding sites in Kazakhstan to date are Tengiz lake, Chelkarteniz lake and the northeastern coast of the Caspian Sea.

The Komsomolets Bay area, Dead Kultuk and Kaidak sors are still regularly used by thousands of birds spending the summer and molting here. Birds from the colony of Central Kazakhstan fly through these areas, increasing the local non-nestling livestock in April and August-September. Up to 35 thousand specimens migrate through Komsomolets Bay annually.

Abai site is located in the north-western part of the Kazakhstani Sector of the Caspian Sea in the area of a water body of the Caspian Sea 60-70 km north of the coast of Buzachi peninsula and geographically belongs to Atyrau region. The site is located in the preserved area of the Caspian Sea.

Al-Farabi site is located in the southern part of the Kazakhstani Sector of the Caspian Sea and geographically belongs to Mangystau region of the RoK. The western border of the Al-Farabi site is adjacent to the state border between the Republic of Kazakhstan and the Russian Federation in the area of a water body of the Middle Caspian Sea.

Mangystau region. There is a massive network of specially protected natural sites on the territory of Mangystau region, including the Ustyurt State Nature Reserve and the Kenderli-Kayasan Preserved Area of republican significance, as well as 8 reserved forests and 1 nature park of regional subordination. Among the reptile species inhabiting the territory of Mangystau region, the Elaphe sauromates wood snake is listed in the Red Book of the Republic of Kazakhstan (2010). The Central Asian tortoise, which is a common, widespread and in some places quite numerous species on the territory of Mangystau, nevertheless it has the status of a vulnerable species upon criterion of the Red List of the International Union for Conservation of Nature (IUCN).

Kenderli-Kayasan preserved area of republican significance was created in order to preserve the habitat and natural reproduction of the houbara bustard and the saker falcon. The established regimes: reserve status, protection regime, controlled regimes.

Karazhanbas deposit is located in the north-western part of Buzachi peninsula, within the Caspian depression, on the territory adjacent to the Caspian Sea from the west. The State conservation area of the northern part of the Caspian Sea borders on the western side of the deposit. As part of industrial environmental control, flora and fauna are monitored twice a year.

Aktobe region. The State integrated nature reserve of local significance ‘Kokzhide- Kumzhargan’. On the territory of this reserve there are two facilities of the state nature reserve fund of republican significance: Kokzhide sands and Kokzhide groundwater, which are included in the List of geological facilities of the state Nature Reserve Fund of republican and international significance.

Urikhtau, Alibekmola and Kozhasai deposits are located in Mugalzhar district of Aktobe region of the RoK. The north-western part of the contract area of the Urikhtau deposit is located in the Kokzhide sands, the deposits also border the state integrated nature reserve of local significance “Kozhide-Kumzhargan”. For the purposes of preventing ground-water contamination, regular environmental monitoring is carried out both in the area of operations of the Group companies and in the area of the Kokzhide sand massif adjacent to the Contract area. Consultations are also ongoing with the authorized bodies in the field of environmental protection and subsoil use to develop the necessary measures for the management of this subsurface area and further safe work practices.

PRODUCTION SITES LOCATED WITHIN BOUNDARIES AND NEAR SPECIALLY PROTECTED NATURAL AREAS (SPNA)

|

Type of SPNA |

Within the boundaries |

Adjacent boundaries (part of territory penetrates through) |

Outside the boundaries (located near 1–10 km) |

|

IUCN I-IV category |

– |

– |

– |

|

IUCN V-VI category |

Isatai Dead Kultuk (Ustyurt) Abay |

Urikhtau |

Alibekmola Kozhasai Karazhambas Rozhkovskoe |

|

World heritage lands |

– |

– |

– |

|

Ramsar lands |

– |

– |

– |

Our contribution to the conservation of biodiversity in 2022:

In line with Environmental Policy, we commit:

- not to carry out activities in specially protected natural areas, being of great value as a habitat for rare animal species and those in danger of passing away and the valuable ones, to make risk assessment when carrying out works in ecologically-sensitive areas;

- when planning and implementing production activities, apply a hierarchy of measures to mitigate impacts on biodiversity, taking into account four key actions: prevention, minimization, restoration and compensation of potential significant direct impacts:

- participate in research programs and industry partnerships to further accumulate knowledge and develop innovative solutions in the field of environmental protection and biodiversity protection;

- to prevent illegal hunting, fishing and other use of objects of flora and fauna resources by their employees, as well as employees of contracting and subcontracting organizations in the contract areas.

CASE STUDY

In 2022, Zhenis Operating LLP, together with Republican state budget-supported enterprise ‘Atyrau sturgeon fish-breeding farm’, carried out work on the production of juvenile sturgeon linkage 1.5 g in the quantity of 28,123 pcs in the amount of 1.4 mln tenge, followed by their release into the Ural river. This work was carried out in order to indemnify against the inevitable damage caused to fish resources and replenish the biodiversity of the Caspian Sea. The place, term, method and technique of fish stocking were carried out in accordance with the scientific recommendations of the research-and-production center of the fisheries of the Republic of Kazakhstan.

The baseline environmental studies, drilling and well testing were carried out at the sites located in the state conservation area in the Northern part of the Caspian Sea. At the present time of activity in these areas, the man-made impact is insignificant and does not prevent the free movement of wild animals and birds in their habitats. During drilling, the following types of work have an impact on the environment: rigging-up, drilling and well testing, navigation. The influencing factors are: increase of concentrations of suspended matter in water during offshore construction, violation of the native structure of bottom sediments, including under the influence of heavy shipping traffic, physical impact of noise.

The operational environmental monitoring of the environment, abandoned wells and scientific research (R&D) on hydrology, hydrochemistry, hydrobiology and ichthyology are carried out within the context of indemnification for the inevitable damage caused to fish resources during production operations.

One of the negative consequences of industrial activity, which also has effect on biodiversity, are electric power transmission lines, which represent a major risk to ornithofauna. The death of birds as a result of wirestrikes and electric shock is becoming one of the most acute problems of wildlife protection, especially in the steppe and semi-desert zones of the country, where the lack of woody vegetation makes power transmission line supports the most attractive for nesting and rest of many species of birds of prey.

Identification and investigation of areas of increased risk of electric installations for birds are carried out in the course of special studies or within the framework of industrial environmental control.

CASE STUDY

In order to exclude the death of birds from electric shock on overhead power lines at the facilities of the trunk lines of KazTransOil JSC in 2022, the works were carried out on the installation of bird protection devices (BPD) in the amount of 12,581.930 thous. tenge, which significantly reduced the probability of bird death when landing on line disconnectors (line isolating switch outdoor two-column). In general, upon the Company 242 sets have been installed in the Zhezkazgan, Shymkent, Atyrau oil pipeline departments.

In KazakhOil Aktobe LLP on the 6 kV overhead line of the Alibekmola and Kozhasai fields in order to prevent electric shock to birds were installed the standoff insulators, excluding touches of the second potential (‘phase’, ‘earth’). On the 35 kV overhead line, the birds electrocution is excluded by the fact that the wires are fixed on suspended insulators, which do not allow touching the second potential.

In December 2022, KMG experts took part in a round table on the topic: ‘Birds and energetics: in search of sustainable development’, organized by the Association of Legal Entities ‘Association of Environmental Organizations of Kazakhstan’. Topical subjects on the implementation of Renewable Energy Sources projects in Kazakhstan, legislation in the field of ornithofauna development, review of information transparency of companies, causes of bird deaths, bird protection devices of overhead power transmission lines and substations were discussed.

|

|

Onshore operations |

Offshore operations |

||||

|

|

2020 |

2021 |

2022 |

2020 |

2021 |

2022 |

|

Sites for which biodiversity is covered by an EIA or similar document (%) |

100 |

100 |

100 |

100 |

100 |

100 |

|

Sites where environmental monitoring is regularly carried out (%) |

100 |

100 |

100 |

100 |

100 |

100 |

|

Sites with abandoned wells where abandoned wells are regularly monitored (%) |

100 |

100 |

100 |

100 |

100 |

100 |

Reducing the negative impact of the activities of the KMG Group of Companies on biodiversity is carried out both within and outside the boundaries of natural areas of protection. The policy in the field of biodiversity conservation provides for the preservation of habitats, migratory routes of animals, minimization and indemnification of possible damage to the environment, reduction of the areas of disrupted areas. Measures to minimize the negative impact include reducing the duration, intensity, as well as direct and indirect levels of impact of works in mining and transportation facilities.

The Company would consider any initiatives, ideas and measures for the conservation of biodiversity and invites to send them to the address hse@kmg.kz.

Training of staff in environmental management issues

Training in HSE, Industrial and Fire Safety remains relevant in the KMG Group of Companies. In this regard, the priority orientation is mandatory education, training and staff qualification raising in these areas.

Since 2022, the mandatory training of KMG Headquarters employees in HSE and Fire safety basics takes place on the platform of KMG Engineering LLP.

The training in Industrial Safety and HSE is conducted according to the ‘70/20/10’ learning model ‘in the workplace/internal/external’ on the basis of own Education-and-Training complexes/centers. Mentorship and internal coaching programs are implemented among experienced employees, master classes and trainings are held, various competitions are held among leading employees, which makes it possible to improve internal communications and motivate staff to aspire to be the best in their profession.

Such companies as Ozenmunaigas JSC (Zhanaozen), KazTransOil JSC (Aktau city), Pavlodar Petrochemical Plant LLP (Pavlodar city) and Oil Services Company LLP (Aktau city) have their own Education-and-Training complexes/centers.

NEBOSH (National Examination Board in Occupational Safety and Health) is an internationally recognized organization offering occupational safety and health qualifications and training of employees. NEBOSH courses are known for their high qualifications and demand in various industries, including the oil and gas industry. NEBOSH training courses help employees of KMG and its subsidiaries to gain practical skills in risk assessment, safety management in the workplace, which, in turn, increases work efficiency and reduces the risks of industrial accidents.

Training sessions and workshops for employees on environmental issues are held on a periodic basis. Thus, in connection with the enactment of the new Environmental Code RoK from 01.07.2021 to clarify the introduced innovations, including on the EIA procedure, environmental design, State Environmental Expertise and its deadlines, the Company employees participated in workshops where the speakers were the drafters of the new Environmental Code and employees of the relevant structural units of the Ministry of Environment and Natural Resources. Based on the workshop results, the participants received certificates.

The level of the employees of the KMG Group of Companies who were trained in 2022 on HSE, by category was the following: Administrative-and-Managerial staff – 2,894, Technical-and- Engineering Employees – 14,236 and Production staff – 61,941 people. In 2022, 7,222 women and 71,849 men were trained, and at a ratio to the overall indicator 79,071 people – 9.1 % of women and 90.9 % of men.

Environmental assessment of the planned economic activity

The Company implements the policy for environmental protection by conducting an environmental assessment of planned and ongoing activities on environment components. Both direct and indirect and cumulative negative impacts are taken into account in the planning and design process. Every intention to develop the production process or create a new project is accompanied by consultations with the public in the form of collecting proposals or open meetings, where every opinion is taken into account in further work. Each project is submitted to public hearings with the participation of non-governmental organizations, government agencies, the public and other interested parties. Public hearings are also open to anyone who wants to take part in them, independently of their place of residence. The results of the hearings are recorded and published available to the public for acquaintance.

Since 2021 the Company has been guided by the Corporate Standard for Environmental Impact Assessment. The standard defines the corporate principles of the assessment process of the projected activity impact for environment, regulates the activities of the KMG Group of Companies, employees and contractors of the KMG Group of Companies, including design organizations whose activities are related to the technical documentation development and Environmental Impact Assessment materials, the organization and accounting of public opinion on environmental impact assessment materials, as well as obtaining a permit for emissions.

CASE STUDY

In 2022, 17 meetings with the local community and public organizations and 100 public hearings were held, press tours to production facilities were carried out. The increase in the number of public hearings is due to the fact that, according to the new environmental legislation, the role of the public in decision-making has been expanded and public discussions are now held at every stage of design. Moreover, with the adoption of the new Environmental Code RoK, emissions from the activities of contracting organizations are included in environmental permits for impact issued to Subsidiaries and Dependent Entities, thus, projects of contracting organizations are discussed within the framework of public hearings of the Operator.

Interaction with public organizations

In 2022, the Public Ecological Council (PEC) of Atyrau Refinery LLP (AR) began its work. The panel of experts includes the plant management, professional ecologists and eco–activists of the region, candidates of technical sciences, Doctor of Economics, deputies, media representatives and city residents. The purpose of the PEC creation is to give possibility to the civil community to participate in the decision-making process of AR production activities, to express the opinion of civil society about the activities of AR in the field of environmental protection, the implementation of environmental projects and the development of effective recommendations in environmental problems solving.

On September 15, 2022, the first PEC meeting was held, a Q-and-A session was held, the PEC members visited the sulfur regeneration plant, the site of mechanical treatment facilities. The AR Management familiarized those present with the progress of the plant’s implementation of the Environmental Protective Measures Plan and told about the status of the Tazalyq project, the progress of its implementation and all construction stages of the Modernization of Treatment Facility on the territory of the plant. The PEC members received detailed information on all their questions of interest, as well as on the improvements and innovations being implemented at the plant.

On November 15, 2022, a regular meeting of the AR Public Ecological Council was held. At the meeting, the plant specialists familiarized the PEC members with the progress of maintenance-and- repair works, the current status of the implementation of the Tazalyq environmental program, and also presented a Roadmap for abatement of emissions into the atmospheric air.

The Roadmap includes such measures as the transfer of filling operations for light petroleum products to a sealed filling overpass, the construction of a vapor recovery unit at the Delayed Coker Unit (DCU) and the installation of pontoons at tank batteries.

The meeting also summed up the results of the implementation of the stages of work under the Tazalyq program: the 1st and 2nd sectors of evaporation fields with a total area of 465 hectares were recultivated, the channel of regulatory cleaned discharged was reconstructed. Recultivation of 3rd and 4th sectors is planned for next year. The works continue on the project ‘Modernization of treatment facilities (MTF)’: next year, oil separators, a sand trap, a flotation unit and PDO-3 (pond of additional sludge) will be dismantled. Currently, the construction of oil slime dehydration and prepurification units has been completed by 98 %.

All announced environmental activities are aimed at environmental impact reduction. After the MTF reconstruction, part of the treated water will be re-used for the needs of the plant – to reduce the fresh water intake for production purposes from the Ural river.

Green office concept in KMG

KMG adheres to the Green Office principles which are aimed at the economical use of all resources and caring for the environment. We are actively engaged on the implementation of measures that will help us to constantly improve working conditions, enhance comfort and efficiency of labour, improve the design and architecture of our offices, increase green spaces and provide with recreation opportunities for our employees. We aim to cut down resource consumption, create a favorable environmental setting and achieve economical effectiveness of our activities, comply with Green Office principles.

Work is underway on environmental education of employees, resources saving (energy saving, heat economy, separate collection, paper save, etc.), and ‘green events’ are also being held.

To date, the following initiatives have been implemented:

- installation of eco-friendly dustbins in offices, corridors, lounges, parking for separate waste collection: paper, plastic, glass and metal;

- installation of special containers for collecting run-down batteries;

- notification to employees – a ‘pop-up window’ on the need to turn off computers and facilities by the end of the working day;

- memo to office employees on the need to preserve trees and minimize printing volume;

- electronic document flow was introduced. The KMG corporate center has set a goal of ‘Reducing the consumption of writing paper by 3 % compared to the level of 2019’. At the end of the year, 2,593 packs of paper were used, which is lower by 54.5 % than the planned figure of 5,710 packs, and also lower by 78.7 % lower than the specified goal (12,228 packs were used in 2019);

- using projectors for presentations;

- information updating on eco-friendly dustbins in the adaptation training course for newly hired employees;

- negotiations are underway to install a recycling kiosk terminal for collection of plastic bottles and glass containers in the building of the KMG corporate center.

CASE STUDY

Participation in the international event ‘Earth Hour’

The international event ‘Earth Hour’ is held annually all over the world. This is a symbolic action of careful attitude to nature, a public call-up for taking measures to preserve the planet climate and its limited resources. In 2022, KMG joined this campaign to energy saving.

CASE STUDY

Commitment to environmental liability is also reflected in the greening work in KMG SDEs. As part of the execution of Instruction of the President of the Republic of Kazakhstan K. Tokayev, regarding the planting of more than 2 billion trees in the forest area and 15 million in settlements, announced in the Address to the people of Kazakhstan, also as part of the implementation of the Comprehensive Plan, the implementation of the action ‘Carrying out greening works by major oil companies’ for 2021–2024 in KMG SDEs located in Atyrau region.

In all KMG SDEs, work has been carried out on planting of vegetation on the territory of sanitary protection zones and in the regions of presence. For example, employees of Karazhanbasmunai JSC replenished the green resources with a total area of 0.2529 ha with 562 units: willow fruits, apple trees, ailantho, maple and ash. By good tradition, the planting of trees is followed by regular care and watering. Pavlodar Petrochemical Plant (PPCP) LLP planted 3,369 trees in the area of 11.2 hectares on the territory of the sanitary protection zone. KazakhOil Aktobe LLP planted 1,126 green spaces on the territory of the fields. This is part of a large and continuous effort to improve the air quality and an essential component of environmental projects.

CASE STUDY

Embamunaigas (EMG) JSC in honor of the 100-th anniversary has arranged the Alley of Fame of petroleum producers in Atyrau city. The EMG management and staff, oil veterans, representatives of the Akimat of Atyrau city took part in the opening of a new location for recreation and communication of citizens.

The alley with an area of 6,300 m2 is located on the Zhaiyk river embankment, near the Embamunaigas JSC office. Historically, this territory is associated with the Embaneft production association, where famous oilmen Safi Utebayev, Bolekbai Sagingaliev, Zholdaskali Dosmukhambetov, Oryngazy Iskaziev and many other discoverers of mineral deposits began their labour path not only in the basin Ural-Embinskiy, but also in Mangystau and Aktobe regions.

The alley represents an urban space, in the center of which there is an architectural-and-sculptural composition: a drop personifying oil and the natural gas flame. The bas–relief of several thematic compositions revealing the history and distinct identity of the region is complemented by a commemorative plaque with the names of Emba oil men – Heroes of Socialist Labour and Laureates of the State Prize. The number of Emba deposits is marked by 47 colonnades. 100 fountains will create a special atmosphere on the territory of the alley. On the territory of the Alley there is a children’s playground, fountains, benches for recreation. In order to create recreational open space for citizens, additional 100 seedlings were planted and the watering was organized.

CASE STUDY

In June 2022, KMG took part in a conference on the topic of ‘Responsible business for sustainable development’ with the participation of ecologists from more than 180 industrial enterprises of the country and international organizations. This event was aimed at strengthening of cooperation and sharing experiences of enterprises, international organizations, on topical issues of environmental protection, climate change and legislative regulation. The conference was timed to coincide with the celebration of June 5 – World Environment Day.

On the initiative of KMG, Badges and Diplomas were awarded to distinguished employees of the Group of Companies on behalf of the Chairman of the Board of KMG. Similar awards were also initiated by the authorized body in the field of environmental protection.