The main decarbonization measures are aimed at reducing direct emissions (Scope 1) through measures to enhance the energy efficiency of fixed combustion sources, reduce gas flaring and strengthen work to methane leak monitoring and a group of measures aimed at reducing emissions from means of transport.

The reduction of indirect emissions (Scope 2) will be carried out through an increase in energy efficiency, an increase in energy consumption from ‘clean’ sources of energy.

Use of energy resources and enhancing energy efficiency

The Company activities in the field of energy saving and enhancing energy efficiency are based on the methodology of the international standard ‘Energy Management Systems’ ISO 50001, which is the best generally recognized international practice for system management in this activity.

Energy policy of KMG

KMG within execution of the KMG Low–Carbon Development Program for the period 2022–2031, the KMG corporate Energy Policy (hereinafter referred to as the Policy) was developed and approved in December 2022, it applies to all subsidiaries of KMG, as well as contractors. The Policy can be viewed at: https://www.kmg.kz/en/sustainable-development/corporategovernance/corporate-documents/

The policy supports procurement and project activities that are effective from the viewpoint of energy consumption, defines responsibility with regard to energy management and, focusing on economic feasibility, practices the introduction of the best available techniques, international practices, standards and administrative decisions aimed at energy saving and enhancing energy efficiency and is an integral part of the KMG Low-Carbon Development Program for the period 2022–2031 and creates the basis for the establishment and analysis of goals and energy objectives.

Energy consumption

The KMG Corporate Center collects and analyzes data on energy consumption and energy efficiency indicators, keeps a close watch on progress and identifies opportunities for improvement, performs benchmarking with the previous period and with the indicators of similar companies in the industry (IOGP).

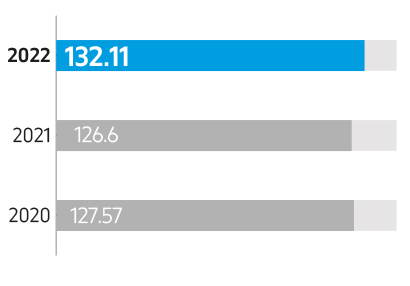

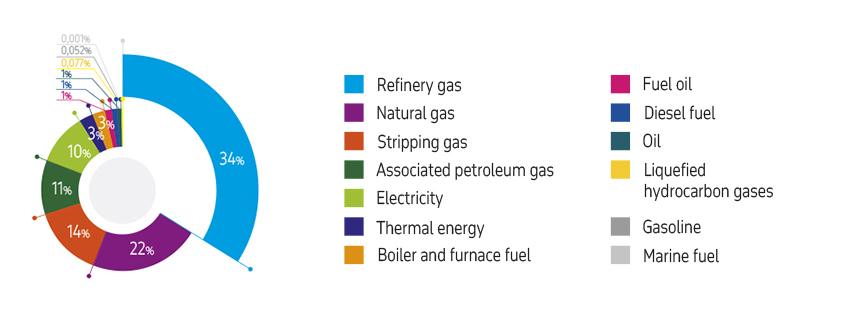

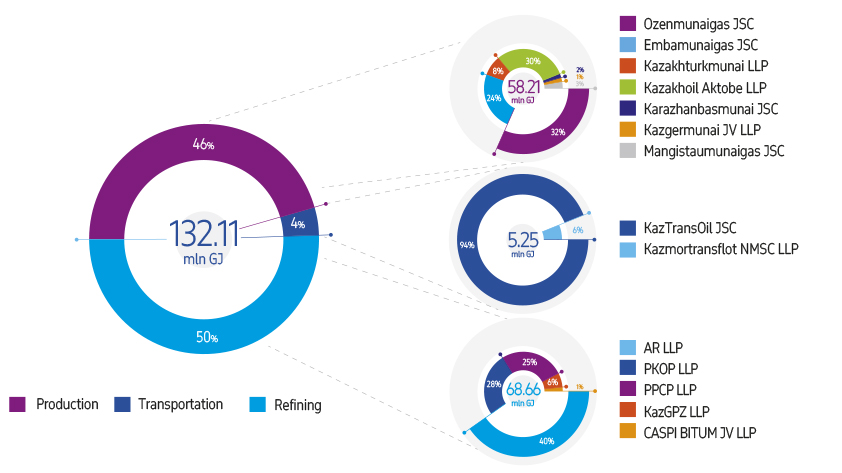

In total, in 2022 were consumed 132.11 mln GJ (4,341.5 thous. ref. fuel) of fuel-and-energy resources (4 % more than in 2021 the increase in energy consumption is associated with the exit into the nominal mode of Kalamkas GTPP after overhaul, as well as an increase in the volume of oil refining by 20 % for PetroKazakhstan Oil Product (PKOP)), including electric energy – 13.23 mln GJ, thermal energy – 3.54 mln GJ, motor fuel – 1.56 mln GJ and boiler-and-furnace fuel – 113.78 mln GJ (at the same time, refinery gas is 34 %, natural gas is 22 %, stripping gas is 14 % and associated petroleum gas (APG) is 11 % of total energy consumption). The volume of energy consumption is distributed among three business areas: ’Oil and gas production’, ‘Oil transportation’ and ‘Oil and gas processing’.

In 2022, the volume of own generated energy for the KMG Group of Companies amounted to 702,646 thous. kW of electric energy and 4,841 thous. Gcal of thermal energy.

Consumption of fuel-and-energy resources (FER), mln GJ

Energy consumption by type of fuel, %

In 2022, in accordance with the Rules of determination of rate for support of renewable energy resources, the AR and MMG purchased electric energy in the amount of 11,929 thous. kW for own needs, produced by facilities for renewable energy use from ‘Accounting and Finance Center for Support of Renewable Energy Sources’ LLP. The electric energy generation by PKOP solar panels for street lighting of the territory in 2022 amounted to 75 thous. kWh.

Energy consumption by business-areas, %

Reduction of energy consumption

Within the execution of the Action Plan for Energy Saving and Energy Efficiency of KazMunayGas JSC NC from 2017 to 2021, 265 measures were implemented, the cumulative effect on saving fuel and energy resources from which amounted to 101,478 tons of reference fuel (about 3 mln GJ), which is equivalent to reducing emissions by 229,490 tons CO2. The total costs for the implementation of the Action Plan for Energy Saving and Energy Efficiency of KazMunayGas JSC NC from 2017 to 2021 amounted to 10,801 mln tenge.

The main strategic directions of the development of energy saving and energy efficiency of the KMG Group of Companies are the modernization of process equipment, the adoption of energy-efficient technologies, optimization of generation and consumption of thermal energy, as well as the development of own generation sources, including using APG.

This year, there were implemented 49 actions under the Low-Carbon Development Plan, the calculated annual savings of fuel-and-energy resources amounted to 2,057 mln GJ, in natural units – 33,448 thous. kW of electricity, 1,531 Gcal of thermal energy, 25,292 tons of boiler and furnace fuel and 21,732 thous. m3 of natural gas, which is equivalent to reducing emissions by 136,703 tons CO2. The total costs for the implementation of energy saving and energy efficiency measures amounted to 10,355 mln tenge.

In 2022, the following main measures to enhance energy efficiency were performed:

- replacement of pumping units in KTO in number of 8 units in Main Petroleum Products Pumping Station (MPPPS) ‘Pavlodar’, in Petroleum Products Pumping Station (PPPS) ‘Ekibastuz’, PPPS ‘Stepnoye’ and MPPPS named after B. Dzhumagaliev against pumping units with a higher efficiency. These measures made it possible to reduce the specific consumption of electricity for oil pumping in technological sites ‘Pavlodar – Atasu’ and ‘Dzhumagaliev – Atasu’. The total calculated savings in terms of volume amounted to 6,694 thous. kWh per year;

- introduction of a variable speed drive in the KTO at Uzen MPPPS, with this the specific electricity consumption for oil pumping in technological site ‘Uzen – Atyrau’ decreased by 11 %. The calculated savings in terms of volume amounted to 2,071 thous. kWh per year;

- optimization of the operating temperature of Atyrau – Samara ‘hot’ oil pipeline by improving the oil mixture rheology in summer time (redistribution of Mangyshlak oil) made it possible to turn off the heater treaters from June to September 2022 in this oil pipeline. The calculated savings in terms of volume amounted to 4,896 thous. m3 per year;

- replacement of control units on the switch desk with variable speed drives on sucker-rod pumps in number of 545 pcs. per KBM. The calculated savings in terms of volume amounted to 1,774 thous. kWh per year;

- introduction of a field control station with variable speed drives for controlling and protecting the electric motors of sucker-rod pumps in MMG. The calculated savings in terms of volume amounted to 4,893 thous. kWh per year;

- replacement of oil heater treaters with life-expired period ‘Modular tube furnace’ PTB –5/40 (6 pcs.) against heater treaters ‘Emulsion heating furnace’ PNE-2.7 in OMG. The calculated savings in terms of volume amounted to 1,577 thous. kWh per year and 15,738 thous. m3 gas;

- optimization of heat flows of the unit CDU/VDU-3 in AR based on the results of PINCH analysis with the installation of additional equipment. The calculated savings in terms of volume amounted to 10,200 tons of fuel gas per year;

- change of the fuel gas supply scheme to the K-8 CDU/VDU-3 column in the AR. The calculated savings in terms of volume amounted to 9,900 tons of process fuel per year;

- modernization of the water heating system of the unit CDU for the sections S-100 of the unit LK-6U in the PPCP. The calculated savings in terms of volume amounted to 1,060 tons of fuel oil per year.

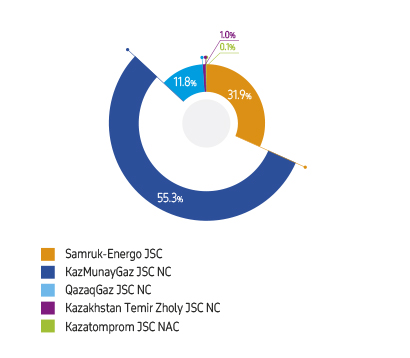

On December 29, 2022, Samruk-Kazyna JSC approved the Program of energy saving and energy efficiency enhancing until 2027. The actions of the KMG Group of Companies, provided for in the framework of the implementation of the LCDP, provide a contribution of more than 55 % into the energy saving potential of this Program. The KMG Department of Low-Carbon Development has defined annual target indicators of energy efficiency for all SDEs for the period up to 2027.

Structure of energy saving potential upon the Energy-and-Resource Saving Program of Samruk-Kazyna JSC up to 2027, tons ref.f.

KMG energy saving potential, provided by LCDP for 2027 (2022–2027)

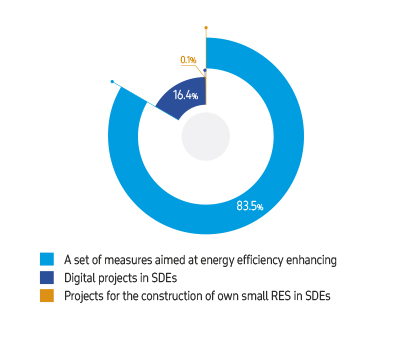

In particular, the KMG energy saving potential provided by LCDP for 2027 amounts to 400 thous. tons reference fuel (near 117 mln GJ) or 10.2 % of the KMG total energy consumption based on the results of 2021. With this, 83.5 % of this potential represent energy-saving measures implemented directly in SDEs, and 16.4 % of the energy-saving potential is associated with the implementation of digital projects.

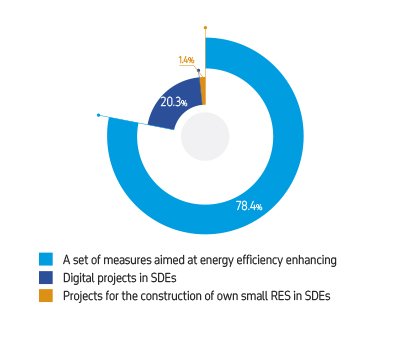

With this, in the KMG Plan for the LCDP implementation about 300 measures are planned to be carried out directly in SDEs, for the period up to 2031, the total energy saving potential from the implementation of which amounts to 541 thous. tons ref.f. (15.85 mln GJ) by 2031 or 13.7 % of the total KMG energy consumption by the end of 2021.

KMG energy saving potential, provided for in LCDP Action Plan for 2031 (2022–2031)

Energy intensity

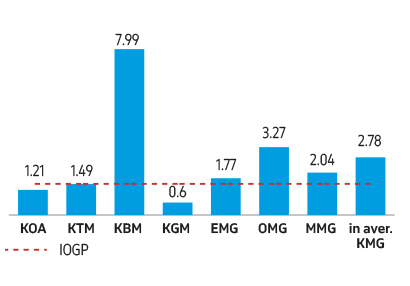

In 2022, the energy density in the area of hydrocarbon production on average for the KMG Group of Companies amounted to 2.78 GJ per ton of produced CH, which remains 85 % higher than the indicator of the International Association of Oil and Gas Producers (IOGP), which in 2021 amounted to 1.5 GJ per ton of produced hydrocarbons. 21

21 The specific cost of energy resources for producing one ton of hydrocarbons in KBM is 5.3 times higher than the worldwide average, according to IOGP data, due to the fact that production from the field Karazhanbas is possible only by oil displacement from underground formation with steam and hot water. The value of specific cost of energy for producing one ton of hydrocarbons in OMG is more than 2.2 times higher than the worldwide average, according to IOGP data. This is due to the high content of dissolved paraffins and the rheological properties of the produced oil, as a result of which, during oil production and transportation, its heating is required not only in winter, but also in summer season.