Air Protection

KMG pays close attention to environmental protection, as it is directly related to the health and well-being of the population. One of KMG Group’s objectives within the framework of its environmental policy is the continuous improvement of environmental protection processes through their digitalisation.

Priority areas for KMG in terms of environmental protection include management of air pollutant emissions, reduction of flaring of raw gas, management of water resources, production waste and land reclamation, and preservation of biodiversity.

The reduction of gas flaring has also reduced air pollutant emissions across KMG Group.

One of the key areas for minimising the environmental impact is reduction of air pollutant emissions from the Company’s operations. Actions to reduce air pollutant emissions include the following activities:

- Obsolete burners on oil heaters are being gradually replaced.

- Integrated gas treatment and processing facilities are under construction.

- Work is underway to install pontoons for vertical oil tanks to prevent evaporation of hydrocarbons.

- Catalytic converters for pollutant emissions are installed on oil heaters, etc.;

- The condition of the furnace burners is monitored systematically, according to the schedule of maintenance and adjustment work;

- The water injection system is being expanded by transferring wells from production to injection;

- The wellhead equipment of production oil wells is updated;

- New steam generation and well sites are commissioned.

- A medium-pressure inter-flare injection burner is installed, designed to burn oil and associated gases in the furnaces of boilers and oil and water reheating furnaces.

In order to reduce the impact on atmospheric air, within the framework of the program “Action Plan with targets for energy and resource conservation and reduction of emissions into atmospheric air until 2031“, the Atyrau Refinery continues work on retrofitting existing oil and petroleum product reservoirs with pontoons.

In the period from 2022 to 2025, work is underway to install pontoons on gasoline and light oil storage tanks in the amount of 12 units. In 2024–2025, work is planned to install pontoons on three gasoline storage tanks and two light oil storage tanks. Also, according to the Tengiz Oil Refining program, it is planned to install pontoons on 9 storage tanks for straight-run gasoline and light oil.

The presence of pontoons prevents evaporation of oil product into the atmosphere, reduces its losses, preserves its quality, reduces fire and explosion safety of the facility, and reduces the negative impact on the environment. Installation of pontoons on tanks is envisaged by the draft Best Available Techniques Guide. The design was developed and manufactured by Maxwell Continental Tank Serv Engineering B.V. (Netherlands) by special order of the Atyrau Refinery in order to reduce its loss, preserve quality, reduce fire and explosion safety of the facility, and to reduce the negative impact on the environment.

The Tazalyq project continues the second stage of the reconstructionof closed-type mechanical wastewater treatment plants: work is underway on the construction of averaging tanks, pumping station buildings, self-washing filter sites and flotators. After completion of the first phase, the upgraded mechanical treatment facilities process an average of 12,000 m³ of oil sludge per month. By the end of 2023, the efficiency of wastewater treatment from oil products reached 83 %. The efficiency of wastewater treatment from suspended solids increased by 20 %. Due to stable oil sludge processing, the volume of oil returned for processing averages 3,280 tonnes per month.

Thus, in 2023, 39,653 tonnes of commercial oil product were returned to refining. This resulted in improved environmental situation and reduced anthropogenic impact on the environment, improved flora and fauna and reduced impact of harmful factors on human health.

The Company pays special attention to monitoring air emissions and natural resources from its production facilities, which are mainly located near or within populated areas. KMG continuously monitors environmental components (atmospheric air, water resources, soil cover, etc.) in order to effectively reduce the negative impact of its operations on the environment.

Environmental monitoring is an integrated system of observations, measurements, collection, accumulation, storage, recording, systematisation, compilation, processing and analysis of the obtained data on the quality of the environment, as well as generation of environmental information on their basis.

To ensure air quality in populated areas, KMG Group is implementing projects to reduce the level of air pollutants, and is also taking actions to organise air quality control systems and install stationary air quality observation posts at the boundaries of sanitary protection zones.

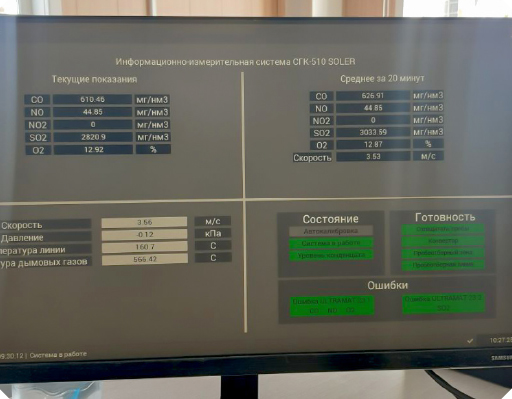

For operators of Category I facilities, in accordance with paragraph 16 of Article 418 of the Environmental Code of the Republic of Kazakhstan from 1 January 2023, the requirement to have an automated emission monitoring system (AMS) is applied. The AMS monitors air emissions at the main stationary emission sources and has an online link with the information system of the authorised body.

In 2023, Mangistaumunaigas JSC and Kazakhoil Aktobe LLP implemented online data transmission from the automated monitoring system (AMS) to the Ministry of Ecology and Natural Resources of the Republic of Kazakhstan (MENR RoK) through connection to National Information Technologies JSC (NIT). At the rest of KMG’s facilities, work on AMS installation is ongoing.

The permitted volume of air pollutant emissions in KMG Group was 119.5 thous. tonnes in 2023 (120.6 thous. tonnes in 2022).

This fact of reduction in air pollutant emissions by 0.9 % compared to 2022 is observed from auxiliary sources (welding, painting).

Gross air pollutant emissions in KMG Group, thous. tonnes

|

|

2021 |

2022 |

2023 |

|---|---|---|---|

|

Total air pollutant emissions, including: |

110.2 |

120.6 |

119.5 |

|

NOx emissions |

12.7 |

16.0 |

15.2 |

|

SOx emissions |

12.2 |

10.5 |

11.0 |

|

other pollutant emissions |

85.3 |

94.1 |

93.2 |

The completed projects for upgrade of oil refineries enabled better environmental performance of fuel produced by the refineries through production of K4-K5 oil products to the European quality standards in compliance with the Customs Union Technical Regulations.

Specific pollutant emissions in KMG Group

|

|

2021 |

2022 |

2023 |

|---|---|---|---|

|

HCs production, t / 1,000 toe of raw hydrocarbons produced |

1.9 |

2.1 |

2.2 |

|

Oil refining, t / 1,000 t of oil refined |

2.8 |

3.1 |

3.0 |

|

Oil transportation, t / 1,000 t of oil transported |

0.5 |

0.5 |

0.4 |

In 2023, the average ratio of NOx emissions to the total produced raw hydrocarbons in oil equivalent for KMG Group amounted to 0.36 tonnes per 1,000 tonnes of HCs produced, while average IOGP value is 0.35. Specific NOx emissions have increased by 13 % versus 2022 due to addition of new emission sources from contractors.

The average ratio of SOx emissions to the total produced raw hydrocarbons in oil equivalent for KMG Group amounted to 0.23 tonnes per thousand tonnes of produced HCs, while average IOGP value is 0.09. Compared to 2022, there is a 9.5 % increase in the specific emissions of SОx.

In its operations, the Company does not emit persistent organic pollutants.

- ECOLOGY AND INDUSTRIAL SAFETY

- Our Management Approach

- Water Management Programme

- Environmental Protection

- Air Protection

- Sustainable Use of Crude Gas

- Waste Management and Land Reclamation

- Decommissioning and Reclamation of Work Sites

- Offshore Well Control

- Oil Spill Prevention and Response

- Biodiversity Conservation and Support of Specially Protected Natural Areas

- Environmental Management Training of Personnel

- Environmental Assessment of Planned Economic Activities

- Public Organisation Engagement

- Green Office Concept in KMG

- Occupational Health and Safety

- Contractor Engagement

- Occupational health, safety, and hygiene