Occupational Health and Safety

KMG and its subsidiaries adhere to the principle that the occupational health and safety takes precedence over operational performance. The Company’s occupational health and safety policy is based on the commitment of top management in this area and aims to involve every employee in creating a safety culture. The Company’s management is committed to zero tolerance for accidents and for the use of alcohol, drugs and psychotropic substances and traffic accidents. The Company is committed to complying with both national laws and the requirements of international and national standards. KMG pays particular attention to ensuring a high level of occupational safety according to global standards and best practices.

As part of IOGP membership, KMG Group has developed and implemented IOGP Vital Rules. To inform employees about compliance with the Vital Rules, campaigns were organised in SDEs by instructing employees and broadcasting videos. A message was sent on behalf of the Chairman of KMG’s Management Board on the importance of compliance with the Vital Rules and the right to refuse unsafe work. Moreover, in order to develop a culture of occupational safety among employees and in accordance with the Action Plan for Occupational Safety of Samruk-Kazyna JSC, in 2023, about 30 thousand employees of KMG and SDEs were trained under the Occupational Safety Culture programme.

At the end of 2023, the number of people injured in work-related accidents decreased by 19 % compared to last year (from 36 in 2022 to 29 in 2023).

The number of road accidents decreased by 21 % (from 24 in 2022 to 19 in 2023), the number of fires decreased by 100 % (no fires in 2023 versus one fire in 2022).

In 2023, there were two work-related fatalities (1 employee of PetroKazakhstan Oil Products LLP as a result of a road accident and 1 employee of Ken-Kurylys-Service LLP as a result of exposure to moving objects).

|

Key OHS Indicators |

UOM |

2021 |

2022 |

2023 |

Deviation 2023/2022 |

% |

|---|---|---|---|---|---|---|

|

Accidents |

Case |

28 |

35 |

28 |

–7 |

–20 |

|

Injured in accidents |

Person |

32 |

36 |

29 |

–7 |

–19 |

|

Including fatalities |

Person |

3 |

1 |

2 |

+1 |

+100 |

|

Road traffic accidents |

Case |

22 |

24 |

19 |

–5 |

–21 |

|

Fires |

Case |

6 |

1 |

0 |

–1 |

–100 |

Lost time injury and fatality accident rates

|

Indicator |

2021 |

2022 |

2023 |

IOGP 1 |

|---|---|---|---|---|

|

Lost time injury rate (LTIR), per mln man-hours |

0.31 |

0.36 |

0.30 |

0.26 |

|

Fatality accident rate (FAR), per 100 mln man-hours |

2.93 |

1.0 |

2.11 |

0.30 |

1Available IOGP figures for 2022 (https://www.iogp.org/).

The Company keeps records within KMG Group and for contractors, contractor data is not included in accident and fatality figures.

Process Safety Management

During 2023, as part of the actions taken to prevent accidents and incidents, consultative and advisory work was carried out to explain to SDEs how to organise and ensure the safety of production processes / barrier management. Also in 2023, 23 scheduled inspections of SDEs’ activities in the field of industrial safety were carried out. 220 items of recommendations were issued to improve the state of industrial safety at hazardous production facilities in KMG Group.

As part of the implementation of KMG Corporate Rules for Isolation of Energy Sources, explanatory work was carried out with SDEs on the implementation of the LOTO industrial safety system. According to the plan, in 2024, work will continue on the introduction and practical application of the LOTO industrial safety system in the production activities of KMG Group.

To systematically improve industrial safety at the facilities of KMG SDEs, an emergency drill was conducted to eliminate an open flow at a well with fire and rescue a victim at the training area of the Zhetybaymunaigas Production Department of Mangistaumunaigas JSC, with the participation of Semser Ort Sondirushi Non-State Firefighting Service, a unit of the Mangistau Branch of Republican Central Paramilitary Headquarters of Professional Emergency Services. The event was observed by representatives of Samruk-Kazyna, KazMunayGas, Department of Industrial Safety Committee, Department of Emergency Situations in Mangistau Region and representatives of KMG SDEs.

During the training, actions were practised to cool the well equipment, reduce the intensity of heat radiation from the flow, determine the zone of contamination, seal the wellhead and kill the well by injecting weighted drilling mud.

Transport Safety

Today, the Company has over 11,000 vehicles and special machines, most of which are operated in major cities and towns in heavy urban traffic, which increases the risk of accidents caused by third parties. Thus, of 19 accidents occurred in 2023, 15 accidents were caused by other road users.

As part of ensuring transport safety, preserving human life and health in the operation and maintenance of vehicles, preventing accidents and reducing the potential risks of injury to Company employees, work is being carried out on a continuous basis to improve transport safety:

- In 2023, SDEs and contractors employees were trained in Defensive Driving in accordance with RoSPA International Standards.

- To raise awareness among KMG Group employees of the need to use seat belts and reduce injuries in road accidents, a practical demonstration of a simulator simulating a frontal collision in a road accident (convincer) is being conducted, which was attended by 7,783 employees of KMG SDEs.

- As part of the project of automated vehicle monitoring system “Travel Management“, in 2023, diagnostics of transport management processes was carried out at KBM, OMG, MMG, OTC, OSC, KTO (roadmaps for project implementation were approved at KBM, OMG, OTC, OSC).

Fire Safety

In 2023 there were no cases of fire at KMG facilities (in 2022 there was one case of fire without injuries due to interruption of operation of electrical equipment).

At the same time, the following fire safety cases were registered: 11 ignitions (Atyrau Refinery (2), OMG (2), OMS, MMG, Petromidia Refinery (2), EMG, Kazgermunai, OSC), 1 flash (OMG), 3 smouldering (KazTransOil, Atyrau Refinery, MMG). According to the applicable laws, “fire”, “ignition”, “smouldering” and “flash” have different signs and definition, therefore all the above cases were not included in the statistics of fires.

To improve fire safety activities, in October 2021, KMG developed and approved a Comprehensive Fire Safety Plan for 2022–2024 with short-, medium- and long-term, as well as preventive actions.

In accordance with the Comprehensive Plan and as part of the execution of the instruction of Samruk-Kazyna JSC, scheduled fire drills were held in all SDEs during the year.

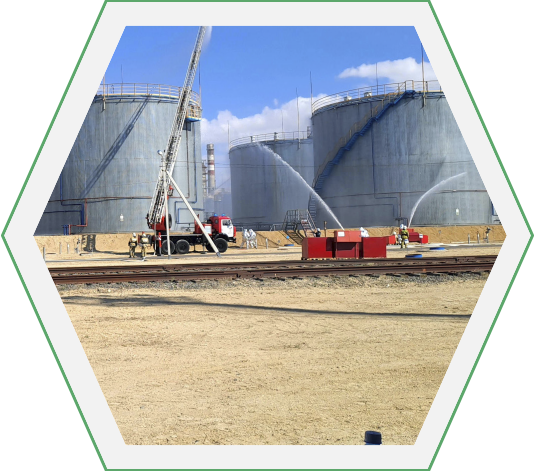

In July 2023, fire drills were held at Mangistaumunaigas JSC with the participation of representatives of Samruk-Kazyna JSC and the Ministry of Emergency Situations of the Republic of Kazakhstan.

On 20 September 2023, fire tactical drills were held to eliminate a fire at the tank farm of JV Caspi Bitum LLP with the participation of the Minister for Emergency Situations of the Republic of Kazakhstan.

Two fire drills with evacuation of people and extinguishing a conditional fire in the building were conducted at KMG Corporate Centre in 2023.

To improve the organisation of work to ensure fire safety, activities to strengthen and explain fire protection standards were carried out in KMG’s SDEs during the year as methodological assistance.

The following initiatives aimed at improving fire safety in the Company are planned for 2024:

- implementation of long-term actions of the Comprehensive Fire Safety Plan for 2022–2024;

- inspection and assessment of the readiness of SDEs and non-state firefighting services to prevent and extinguish fires at the Company’s facilities.

Digitalisation of the HSE Function

To improve transport safety, create a culture of safe driving and a single centralised digital platform, Travel Management, a pilot project to introduce the automated vehicle monitoring system was completed in 2022 at EMG.

Given the positive effect on transport safety as a result of the introduction of Travel Management, an automated vehicle monitoring system at EMG, as part of the phased replication of the project to other KMG SDEs, in 2023, diagnostics of transport management processes was carried out at KBM, OMG, MMG, OTC, OSC, KTO (roadmaps for project implementation were approved at KBM, OMG, OTC, OSC).

As part of the digitalisation of industrial safety processes, the process of introducing an electronic PTW system at EMG continues. Starting from December 2023, the system of electronic PTW has been put into operation for all production units of EMG.

Also in 2024, work was carried out to develop TUMAR, an automated intelligent system for industrial safety aimed at preventing incidents and reducing the negative impact on employees during hazardous process operations and during underground workover operations.

- ECOLOGY AND INDUSTRIAL SAFETY

- Our Management Approach

- Water Management Programme

- Environmental Protection

- Air Protection

- Sustainable Use of Crude Gas

- Waste Management and Land Reclamation

- Decommissioning and Reclamation of Work Sites

- Offshore Well Control

- Oil Spill Prevention and Response

- Biodiversity Conservation and Support of Specially Protected Natural Areas

- Environmental Management Training of Personnel

- Environmental Assessment of Planned Economic Activities

- Public Organisation Engagement

- Green Office Concept in KMG

- Occupational Health and Safety

- Contractor Engagement

- Occupational health, safety, and hygiene