Occupational health, safety, and hygiene

The Company has implemented an occupational health and safety management system in accordance with RoK laws and international standards for occupational health, safety, and hygiene. KMG has a proactive policy to protect its employees’ health and wellness, irrespective of the production process.

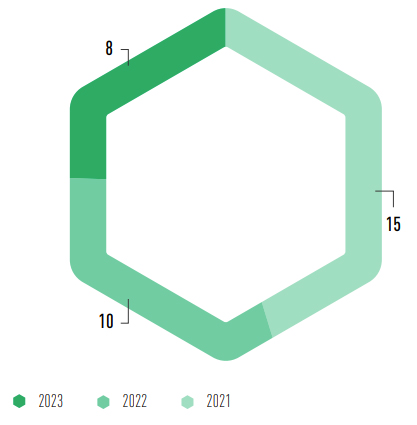

The number of non-injury-related fatalities among employees of SDEs decreased by 2 cases, or 20 %, compared to 2022, this indicator is mainly due to the presence of cardiovascular disease among employees.

NUMBER OF NON-INJURY-RELATED FATALITIES

KMG Personnel Health Management Programme

As part of the implementation of the Strategic Initiative “Personnel Health Management“, KMG Group Personnel Health Management Programme was approved by the decision of the KMG Management Board dated 23 December 2022 (Minutes No. 68). The purpose of the programme is to improve the quality of medical services and provision of medical care at production facilities, introduction and implementation of actions to improve the health of employees in KMG Group.

The main objectives of the KMG Personnel Health Management Programme are:

- Improving the quality of medical care and medical services to employees of KMG Group’s production facilities;

- Developing the mechanisms to strengthen personnel engagement and motivation for healthy lifestyle;

- Improving working, recreation and living conditions for employees of KMG Group’s production facilities.

In 2023, as part of the Personnel Health Management Programme, actions in the areas of industrial hygiene have been developed and approved:

- Action Plan for Personnel Health Management in KMG Group for 2023–2025;

- Corporate Standard on Organising Mandatory Medical Examinations in KMG Group;

- Regulations on the Preparation of a Unified Standard Programme of Industrial Sanitary Control in KMG Group;

- Regulations on the Organisation of Emergency Medical Service in KMG Group, new edition.

In 2023, a number of workshops were held with KMG SDEs on the following topics: Explanation of the requirements of the Regulations on the Preparation of a Unified Standard Programme of Industrial Sanitary Control in KMG Group and the Corporate Standard Organising Mandatory and Periodic Health Chechups in KMG Group. In addition, the situation for 2023 in terms of the number of non-work-related fatalities due to a sharp deterioration in the health of employees was analysed, the experience in implementing an Electronic Health Checkup System (EHCS) in KazTransOil presented for consideration, and recommendations were given to improve the work of SDEs and medical service providers.

Medical Emergency Drills

In accordance with the Regulations on the Organisation of Emergency Medical Service in KMG Group, the Emergency Medical Response Plan is tested annually and on a regular basis at each production facility by conducting medical emergency drills. In 2023, more than 560 medical emergency drills were held at the facilities of SDEs, including with the participation of contractors located in the production areas. Medical emergency drills were held on the following topics: first aid in case of a fall from height, loss of consciousness, poisoning, cardiac arrest, etc. In Mangistau Oil Pipeline Department of KazTransOil JSC, a medical emergency drill was held with the involvement of emergency rescue, firefighting and ambulance medical services. Reports were drawn up for each medical emergency drill held, taking into account the non-compliances and corrective actions.

Electronic Health Checkup System

Starting from 2021, the Electronic Health Checkup System (EHCS) has been introduced in SDEs. The system automates and simplifies the process of examining the health of employees during checkups. Within 5 minutes, the EHCS hardware system can analyse up to 10 key health parameters of an employee and issue a report or a travel voucher. If the EHCS hardware system detects any abnormalities in the employee’s health, he or she is referred to a doctor for examination.

By the end of 2023, 45 units of EHCS hardware complexes have been introduced in the following subsidiaries and affiliates: Embamunaigas JSC – 10 units, KazTransOil JSC – 25 units, Atyrau Refinery LLP – 3 units, Pavlodar Oil Chemistry Refinery LLP – 1 unit, Karazhanbasmunay JSC – 4 units and Mangistauenergomunai LLP – 2 units.

The automation of health checkups avoids the following disadvantages:

- errors due to human factor;

- obtaining unreliable information;

- concealment of true examination results;

- long time for examinations involving medical staff;

- physical logging and storage.

EHCS Advantages:

- Full automation of health checkup process, elimination of the human factor, the possibility of obtaining the most reliable, unbiased information;

- Relatively accelerated health checkup in time;

- Possibility of electronic logging;

- Possibility of photo and video recording of the process.

One of the important problems is the study of the combined effect of industrial health hazards in production conditions and joint exposure (e.g., microclimate, noise, vibration, aerosols, work stress, etc.), the prediction of the effects of their action, as well as the study of the development of occupational pathology.

To solve this problem, SDEs are obliged to conduct industrial control in accordance with the laws of the Republic of Kazakhstan and internal documents in KMG Group. Thus, based on Order No. 62 dated 7 April 2023 of the Minister of Health of the Republic of Kazakhstan On Approval of the Sanitary Rules “Sanitary and Epidemiological Requirements for Industrial Control“, the Regulations for the Preparation of a Unified Standard Programme of Industrial Sanitary Control in KMG Group were developed and approved.

The main tasks of industrial sanitary control include organisation of control over the state of industrial and environmental conditions, including during laboratory tests and research, organisation of industrial control over the quality and safety of food products, food raw materials, public catering products, organisation of control over compliance with standards and technical conditions, requirements of regulatory documents of products, works and services at all stages of production activity.

No occupational diseases have been registered in KMG Group.

- ECOLOGY AND INDUSTRIAL SAFETY

- Our Management Approach

- Water Management Programme

- Environmental Protection

- Air Protection

- Sustainable Use of Crude Gas

- Waste Management and Land Reclamation

- Decommissioning and Reclamation of Work Sites

- Offshore Well Control

- Oil Spill Prevention and Response

- Biodiversity Conservation and Support of Specially Protected Natural Areas

- Environmental Management Training of Personnel

- Environmental Assessment of Planned Economic Activities

- Public Organisation Engagement

- Green Office Concept in KMG

- Occupational Health and Safety

- Contractor Engagement

- Occupational health, safety, and hygiene