Water resources are vulnerable and already exposed to the impacts of climate change and variability, resulting in a wide range of impacts on communities, human health, economy and the natural environment. KMG’s priority is to reduce and, where possible, avoid negative impacts on water resources arising from operations and product deliveries.

The Company’s approach to sustainable development issues is based on the alignment of the Company’s interests and plans with the basic principles of the United Nations, universal human values, global trends and priorities of Kazakhstan’s development. The Company adheres to 17 UN Sustainable Development Goals, one of which is Goal 6 Water and Sanitation. Sustainable Development Goal 6 – ensure availability and sustainable management of water and sanitation for all – is closely interrelated with all other SDGs.

SDG 6 expands the scope centred on drinking water supply and basic sanitation to include water management, wastewater treatment and ecosystem conservation across all kinds of boundaries. The inclusion of these aspects is a crucial first step towards addressing sectoral fragmentation and ensuring coherent and sustainable management, i.e. towards a sustainable water future.

According to the Environmental Policy, KMG and its Subsidiaries and Dependent Entities express their commitment to the principles of sustainable development and include environmental protection and prevention of negative environmental impact among the main priorities of their activities.

The Company has committed to ensuring continuous improvement of water management processes, implementation of water conservation and recycling projects, assessment and management of risks associated with water scarcity.

In order to improve the efficiency of water resources use and protection, define actions and targets to reduce water withdrawal and water consumption, increase water recycling and water reuse, reduce pollutant discharges and environmental impact of KMG in 2023, the Water Management Programme for a 10-year period in KMG Group (hereinafter referred to as the Programme) was developed. The Programme is aimed at addressing the issue of preventing water scarcity to preserve ecosystems, to ensure the planned economic growth, and to improve the water management system across KMG Group. he boundaries of the Programme included KMG’s main operating SDEs, and an analysis of KMG’s investment projects was also carried out. The Programme is expected to be approved in 2024.

Within the framework of the Programme, 3 scenarios of water management development for KMG Group were defined: the baseline scenario, the green development scenario, and the intensive reduction scenario. Under the Programme, an aggregated comparative analysis of water management development scenarios of KMG SDEs was carried out and possible rational options for achieving the greatest effect on water conservation and preservation were presented.

The baseline scenario includes activities with an approved budget that are being implemented or are planned to be implemented as part of SDEs’ business plans.

The activities of the green development scenario include activities of the “baseline scenario“, as well as activities on technical audits of water consumption and sanitation systems: audits to assess the remaining service life of equipment and its suitability for operation, audits at pumping facilities, treatment facilities, evaporation ponds; audits of the water footprint of the final product.

The intensive reduction scenario is the implementation of additional actions implying intensive reduction of water consumption and sanitation, requiring significant financial investments, which is the most expensive development scenario. This scenario includes actions of the baseline and green development scenarios, as well as actions to carry out basic designs with subsequent implementation of process solutions to achieve “Zero Water Discharge“, installation of SMART systems of measuring devices-analysers and geomembranes on evaporation ponds, etc.

Based on the analysis of development scenarios, the Programme recommends to implement the green development scenario with full implementation of the action plan with gradual transition to the intensive reduction scenario after the audits planned in the Programme.

In addition, the Programme analysed the Company’s water footprint, identified categories of water management risks and recommendations for their minimisation, studied the topic of best available techniques and correlated them with the proposed actions.

Improving our approach to water management in line with the Programme will provide greater certainty about the nature of water resources, the diverse needs for these resources and the dynamic balance between water supply and demand. Most importantly, these steps will enable us to value water for its diverse uses and make decisions that enhance efficient, equitable and sustainable water management.

KMG WATER PRINCIPLES

Water is the basis of life, the source of all things existing.

The stability and security of the state is determined by the abundance of clean fresh water, and the success and sustainability of business – by

responsible, caring attitude to it. These principles express the Company's commitment and demonstrate its intention to conserve water resources for

people, nature and well-being of current and future generations of our country

We constantly use water - from daily needs to the extraction and processing of oil. And at the same time, within the daily routine, we must not forget how

much water is priceless. Every employee of the Company can and should contribute to its preservation.

KazMunayGas NC JSC CEO

Water Conservation and Sustainable Use

The Company strives to improve the efficiency of water resources utilisation, reduce the volume of fresh water consumption, and increase the volume of recycling and reuse of treated wastewater.

KMG’s mission is to develop natural resources in an effective and sustainable manner to ensure energy security, development and prosperity of Kazakhstan, caring about future generations.

The main principles of KMG in terms of water resources utilisation are the “Eight Water Principles“. These principles are reflected in the Water Management Corporate Standard approved in 2018 (hereinafter – the Standard).

The Standard systematises the approach to water management in KMG’s SDEs, and helps to increase the commitment of the Company’s managers and employees to the issue of fresh water conservation. Following the approval of the Water Management Programme, an update of this corporate standard is expected this year. The Company operates in full compliance with international requirements, environmental and water legislation. The Company develops draft standards for pollutant discharges, conducts calculations in accordance with methodologies approved by the authorised body, obtains environmental permits and special water use permits.

Atyrau Refinery’s closed-type mechanical treatment facility

Atyrau Refinery’s closed-type mechanical treatment facility

In order to improve the efficiency of water resources use, reduce the volume of fresh water consumption, increase the volume of recycling and reuse of treated wastewater, the following actions are being taken and are planned to be taken on a permanent basis in KMG SDEs:

- update, reconstruction of existing units for mechanical, chemical and biological treatment of domestic wastewater, replacement of old treatment equipment with more modern modular units;

- design of works to reconstruct evaporation fields;

- retrofitting of treatment plants with additional technologies (reverse osmosis), which will subsequently make it possible to use this water to produce steam for industrial needs;

- replacement of old drinking water pipelines with new ones to reduce leaks and process losses of fresh drinking water;

- reconstruction of mechanical treatment facilities (MTF) within the framework of the TAZALYQ project, which will increase the capacity of MTF by 2 times and achieve the maximum permissible discharge limits for the content of oil products and suspended solids in wastewater sent to the biological treatment unit.

- reconstruction of regulatory treated effluent canal and reclamation of Atyrau Refinery evaporation fields;

- construction of a wastewater post-treatment unit using reverse osmosis under the TAZALYQ project;

- complete reconstruction and update of the system of wastewater treatment facilities of PetroKazakhstan Oil Products LLP, subsequently the efficiency of industrial wastewater treatment for oil products and suspended solids was improved from 76 to 98 %, which reduced the environmental load by reducing air emissions.

Ensuring wide accessibility of environmental information and transparency of the Company’s environmental activities to the public, shareholders, interested governmental authorities and other parties is one of the postulates of the Environmental Policy of KMG.

Since 2020, the Company has been calculating its water footprint and posting information on water management on the Carbon Disclosure Project site as part of the Water Security Questionnaire.

In 2023, based on the results of the published questionnaire for 2022, KMG was assigned a “C“ rating for water safety. However, the Company plans to gradually improve this rating as part of the implementation of Programme.

More detailed information can be found in KMG’s published reports, which are publicly available here: CDP Water Security Questionnaire.

KMG implements social projects aimed at solving water supply issues in the regions where it operates, such as “Reconstruction of the Astrakhan-Mangyshlak Water Main“ and “Construction of Seawater Desalination Plant in Kenderli“.

In December 2023, the implementation of the first stage of the project “Reconstruction and Expansion of the Astrakhan-Mangyshlak Water Main“ was completed. The project is aimed at increasing the capacity of the Astrakhan-Mangyshlak Water Main and renewing worn-out equipment to supply water to the population, agricultural producers, industrial and oil and gas producers of Atyrau and Mangistau regions. The Astrakhan-Mangyshlak Water Main is the only centralised source of water supply for consumers in Kurmangazy, Isatai and Zhylyoi Districts of Atyrau Region, as well as for Zhanaozen, Beineu, Mangistau, Karakiya and Tulparagan Districts of Mangistau Region. Every year, the population’s water consumption grows by 4-5 %.

The construction of a 50,000 m3/day Seawater Desalination Plant in Kenderli has also started. This project will solve the problem of drinking water shortage for the residents of Zhanaozen and will also have a multiplier effect on the development of tourism, entrepreneurship and agriculture. Construction is planned to be completed by the end of 2024, and the plant is expected to reach its design capacity in spring 2025.

Earlier, at the Karazhanbas field of Karazhanbasmunay JSC in Mangistau region, a formation water desalination plant was launched to solve the issue of water supply to the field.

When reaching full capacity, the processing of formation water will amount to 42.5 thousand m3/day, while the production of desalinated water will reach 17.0 thousand m3/day, which will release a significant amount of water for the needs of the population of the region. Due to the implementation of this project, by the end of 2023, the volume of fresh water withdrawal at KBM decreased by 2.2 million m3 compared to 2022.

Also, Ozenmunaigas utilised underground water intake wells of albsenomanic water for production needs, thus reducing seawater intake by 25 %.

In 2023, a 2000 m3 vertical stock tank for an emergency supply of production water was constructed at CASPI BITUMEN, thereby increasing the reliability of the plant’s water supply by increasing the emergency supply of production water to 2000 m3 (up to 3.5 days of operation of the plant in case of incidents on the pipeline). A project is being implemented to optimise the reuse of treated wastewater for irrigation of green areas. Work was carried out to divert treated wastewater from the WWTP to the WTP section of the bitumen plant using the NK-2 Du-400 line.

At KGM’s head office, a block-module of deep bio-treatment facilities was replaced in 2023, which will allow up to 50 % of treated water to be reused for irrigation of green areas.

The PetroKazakhstan Oil Products LLP reconstructed and updated the treatment plant system. As a result, the following facilities were put into operation:

- wastewater pretreatment facility for reuse;

- ultrafiltration and reverse osmosis system. The output water is used as make-up water for the recycled water facility after mixing partially with water from wells;

- new sections “vertical oil trap“ and vertical tank for dissolved air flotation were installed instead of the existing part of wastewater pretreatment;

- automatic oil and sludge removal devices were installed in the wastewater pretreatment section;

- caps were installed at the head of the wastewater pre-treatment section to collect odour gases and transport them to the deodorisation system;

- a deep wastewater treatment unit.

Thanks to the completion of the update of treatment facilities at PetroKazakhstan Oil Products, the efficiency of industrial wastewater treatment for oil products and suspended solids was improved from 76 to 98 %, which reduces the environmental load by reducing air emissions.

Information on Water Supply Projects can be found in the Implementation of Investment Projects Section.

Water Footprint

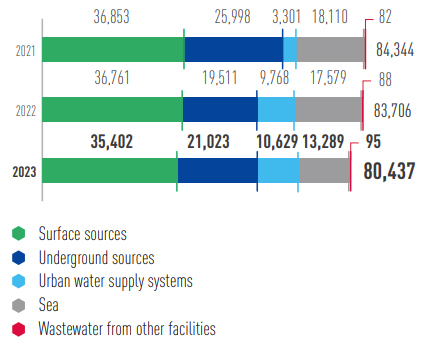

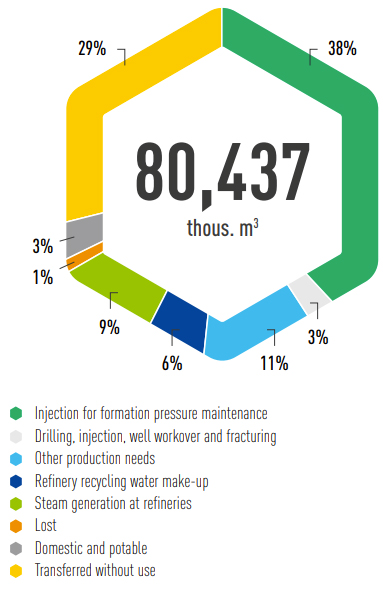

Water intake for the KMG Group of Companies in 2023 amounted to 80.44 mln m3, including: surface sources – 35.40 mln m3, underground sources – 21.02 mln m3, municipal water supply systems – 10.63 mln m3, sea – 13.29 mln m3, wastewater from other companies – 0.1 mln m3. The volume of water consumption for production needs in the category with salinity up to 1000 mg/l was 37.58 mln m3 and 1000 mg/l or more – 42.85 mln m3.

At the same time, we note that the total volume of water withdrawal of 80.44 mln m3 also includes the volume of the subsidiary providing services for supply of fresh technical water to consumers of Atyrau and Mangistau regions – 24.16 mln m3, i.e. this volume is not used by KMG for its economic, drinking and/or production needs. In this regard, excluding the above mentioned volume, the total volume of water consumption by KMG Group for own needs was 56.27 mln m3 in 2023.

WATER WITHDRAWAL FOR KMG GROUP BY SOURCE

thous. m3

According to studies conducted and published by the World Resource Institute (WRI), Kazakhstan is classified as a critical level of water resource exploitation and a very high level of water stress is predicted in the next 15-20 years.

The Company also analyses and records the facilities of KMG SDEs located in regions with increased water scarcity according to WRI Aqueduct1, relating to the basins of the Caspian Sea, the Syrdarya and the Ural Rivers. The total water withdrawal of these facilities was 27.32 mln m3.

In regions with high water scarcity, KMG is developing water management actions to use less fresh water, increase recycled water and closely monitor water use.

At the same time, we note that the need for water resources in production activities is a prerequisite for technological processes.

In 2023, 11.23 mln m3 of wastewater was removed by KMG Group After wastewater treatment at treatment facilities, the standard-quality treated water is discharged to dedicated collectors: gathering ponds, evaporation and filtration fields. There is no discharge to surface water bodies or terrain. Facilities that have no own collectors have their wastewater treated and discharged by dedicated companies under contracts.

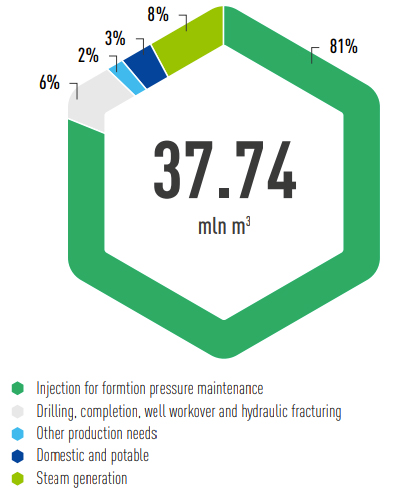

WATER USE BY TYPE OF OPERATIONS(within KMG Group in 2023)

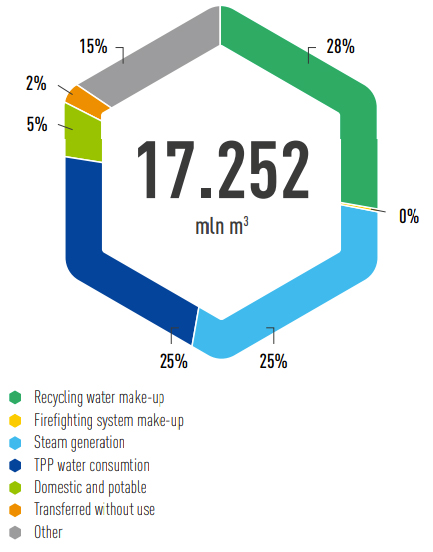

WATER USE BY TYPE OF DOWNSTREAM OPERATIONS ((in 2023 )

The total volume of wastewater transferred was 0.77 mln m3 (with salinity over 1000 mg/l). There is no discharge of wastewater with salinity up to 1,000 mg/l.

At the same time, the discharge of wastewater from facilities in regions with water scarcity was 2.9 mln m3, of which 2.86 mln m3 were discharged to their own receivers and 0.04 mln m3 were transferred to dedicated companies (receiving facilities).

Wastewater should be considered as a sustainable source of water, energy, nutrients and other recoverable by-products, not as a heavy burden.

Our treatment facilities are designed to treat wastewater contaminated with petroleum products and suspended solids. For example, at the refinery, wastewater undergoes separate parallel mechanical and physical-chemical treatment in sand traps, oil traps, radial settling tanks and flotators. The treated industrial wastewater after the flotators goes to biological treatment.

One of the most important tasks of the Company is to increase the reuse of treated wastewater by returning it to the technological process, using it for irrigation of green areas, dust suppression at construction sites and roads. Portion of treated wastewater is reused to wash vehicles, suppress dust and make up firefighting systems. However, a considerable portion of treated wastewater is only reused by refineries, which reused 4.28 mln m3 of treated wastewater in 2023, mainly to make up recycling water supply units. KMG plants reused 25 % of water(of water withdrawal for oil refining).

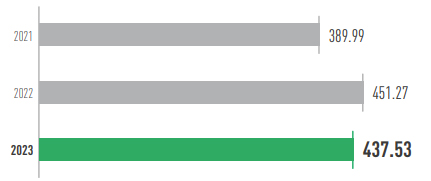

In 2023, recycling water supply systems of KMG refineries used (recycled) a total of 437.53 mln m3 of water.

CIRCULATING WATER SUPPLY SYSTEMS OF KMG

REFINERIES CONTAINED(Recycing water volume, mln m3)

REINJECTED TO MAINTAIN FORMATION

PRESSURE(Produced associated formation water, mln m3)

Oil production generates large volumes of so-called associated formation water: water-oil emulsion is brought to surface, which is then separated into water and oil by gravity. After settling in this manner, water is injected into the formation.

Out of 136.96 mln m3 of produced associated formation water in 2023, 97 % was reinjected to maintain formation pressure.

The Company has a considerable impact on water bodies in the West Kazakhstan (Ural River, Kigach River, Kokzhide Sands), which have special environmental, economical, historical and cultural, and recreational value. Regular environmental monitoring is conducted by regulatory authorities to prevent adverse impact on susceptible ecosystems.

WATER USE BY TYPE OF UPSTREAM OPERATIONS (in 2023 )

Atyrau Refinery’s closed-type mechanical treatment facility

Atyrau Refinery’s closed-type mechanical treatment facility